Fixed Corrugated Rotary Die-cutter Machine

T-ONE fixed corrugated rotary die-cutter machine full line with PLC control, the rotary die cutting machine can store and load order data for quick order change and friendly operation.

T-ONE rotary die-cutting machine with remote control via internet to achieve fast problems shooting

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-FS1200X2200 Fixed Corrugated Rotary Die-cutter Machine

(Fixed structure,top printing,vacuum transfer)

Main Parameters:

Model | T-FS920 | T-FS924 | T-FS1224 | T-FS1228 |

Max. Speed(pc/min) | 350 | 350 | 350 | 300 |

Max Feeding Size(mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 |

Min Feeding Size(mm) | 300×600 | 300×600 | 350×600 | 350×600 |

Skip Feeding(mm) | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 |

Max. Printing Size(mm) | 900×1950 | 900×2350 | 1100×2350 | 1100×2750 |

General features

Fixed units with vacuum transfer.

Printing register is servo control to realize high printing, IR or UV dryer could be installed.

Full line with PLC control, non-stop for printing plate change is optional.

It can store and load order data, quick order change and friendly operation.

Unit features

- Printer Unit: quick change of printing plate(non-stop for printing plate change is optional), imported doctor blade inking system

- Varnishing Unit: UV or water-based varnishing is available

- Double creaser Slotter Unit: single shaft with double slotting knives

- Die-Cutter Unit: servo motor drive, no any vibration to the printer unit, so the printing register is promised.

- Dryer Unit: IR lamp or UV dryer system is optional.

Product Detailed

Feeder Unit

latest lead-edge feeding table original from Sun Automation, stable and quick.

Printer Unit with Vacuum Transfer

The printing cylinder is made of fine materials with harden treatment and chrome plating, done the dynamic balance correction can running smoothly and stable.

Servo motor driving for printing roller register, adapts Endat high-precision encoder, efficiently ensure the servo rotating system control precision; Printing register control system connected to the servo directly, achieve quick response and high precision.

Transverse register is digitally controlled by motor and PLC.

Printing plate is quickly changed, and fast tilt error calibrated occurred in mounting plate within the scope of modification.

Whole vacuum adsorption with high precision transferring (all transferring wheels are made of aluminum alloy with ceramic spaying on the surface), can achieve high printing accuracy.

Whole vacuum absorptive bearings are with harden treatment and chrome plating, the gap adjusted by motor and PLC.

The diameter of the Ceramic anilox roll is increased, the steel roller is covered with ground treatment ceramic, laser engraving the Anilox is more abrasion resistant than the steel anilox roll and have long time service using.

The caliber of the Anilox roller is adjusted by motor and PLC.

All printer units are fixed together, the distance between each unit is widened for conducing to the ink drying and ensure the printing precision. Each printer unit is equipped with hot air drying system.

A Fixed device of printing register and brake is controlled by Servo motor. Upon closing or cleaning the unit, the positions are precisely restored so the unit is ready for production without adjustment.

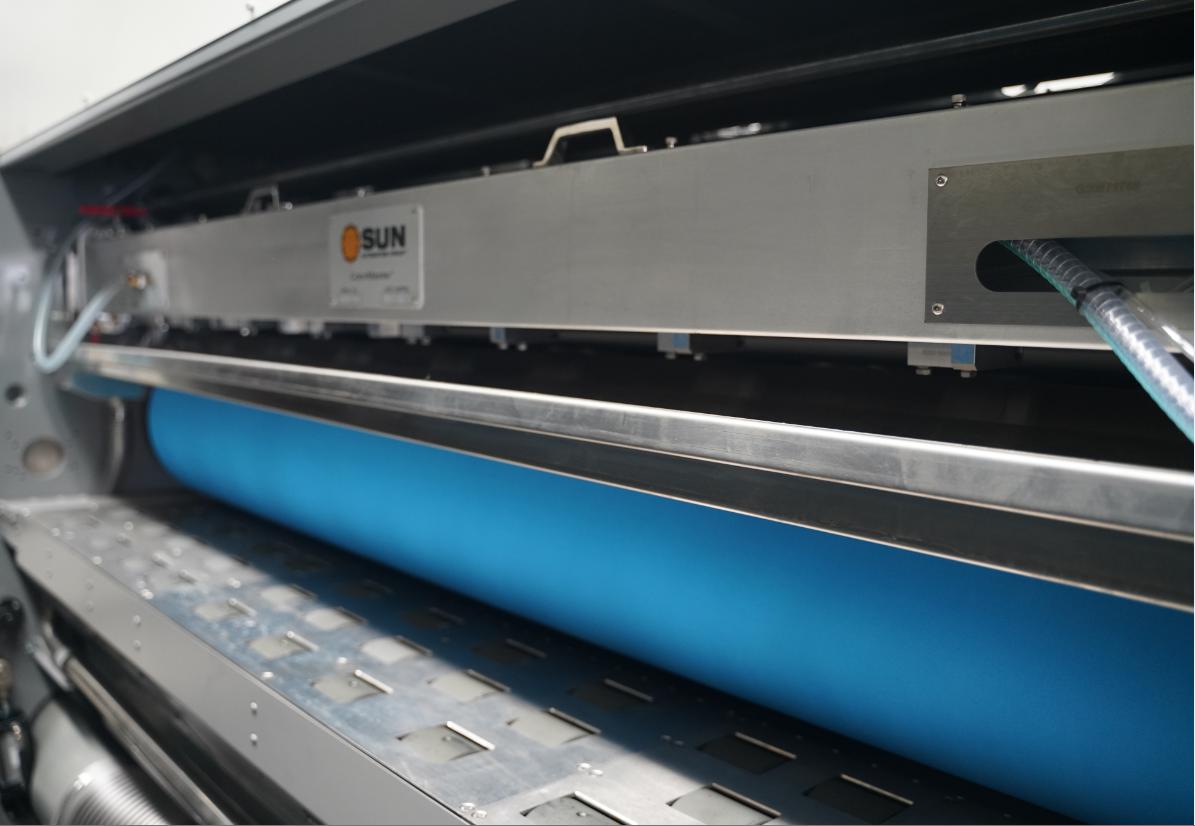

Seal Groove Chamber Single-Doctor blade inking system (Imported from Sun)

1. The main body of ink cavity is non-metal materials used but special polyurethane, never be rusted, and easy to clean.

2. No need both terminal seal as the traditional dual doctor-blade to avoid both sides leakage problems, and also save the machine running time.

3. No need the traditional dual doctor-blade seal knives, which can decrease the costing.

4. The whole cavity body is evenly allocated with the air/pressure sac regulation. The ink scraping pressure is allocated at the left, right and middle.

5. Ink short automatic alarming device is adopted to avoid damage of the blades and ceramic anilox.

6. Automatic cleaning system is adopted on the doctor blade and ceramic anilox roll.

Cleaning function can be automatically switched to ensure the ink recycling thoroughly; Ink saving function can save more ink on each unit at each time during cleaning or color changing.

Automatic resetting is controlled by Servo after cleaning the printing plate.

Varnish Unit ( Work as printer unit also )

Water-based varnish or UV varnish could be used .

Widened unit width is helpful for varnish dry.

For safe operation, paperboard blocked sensor applied.

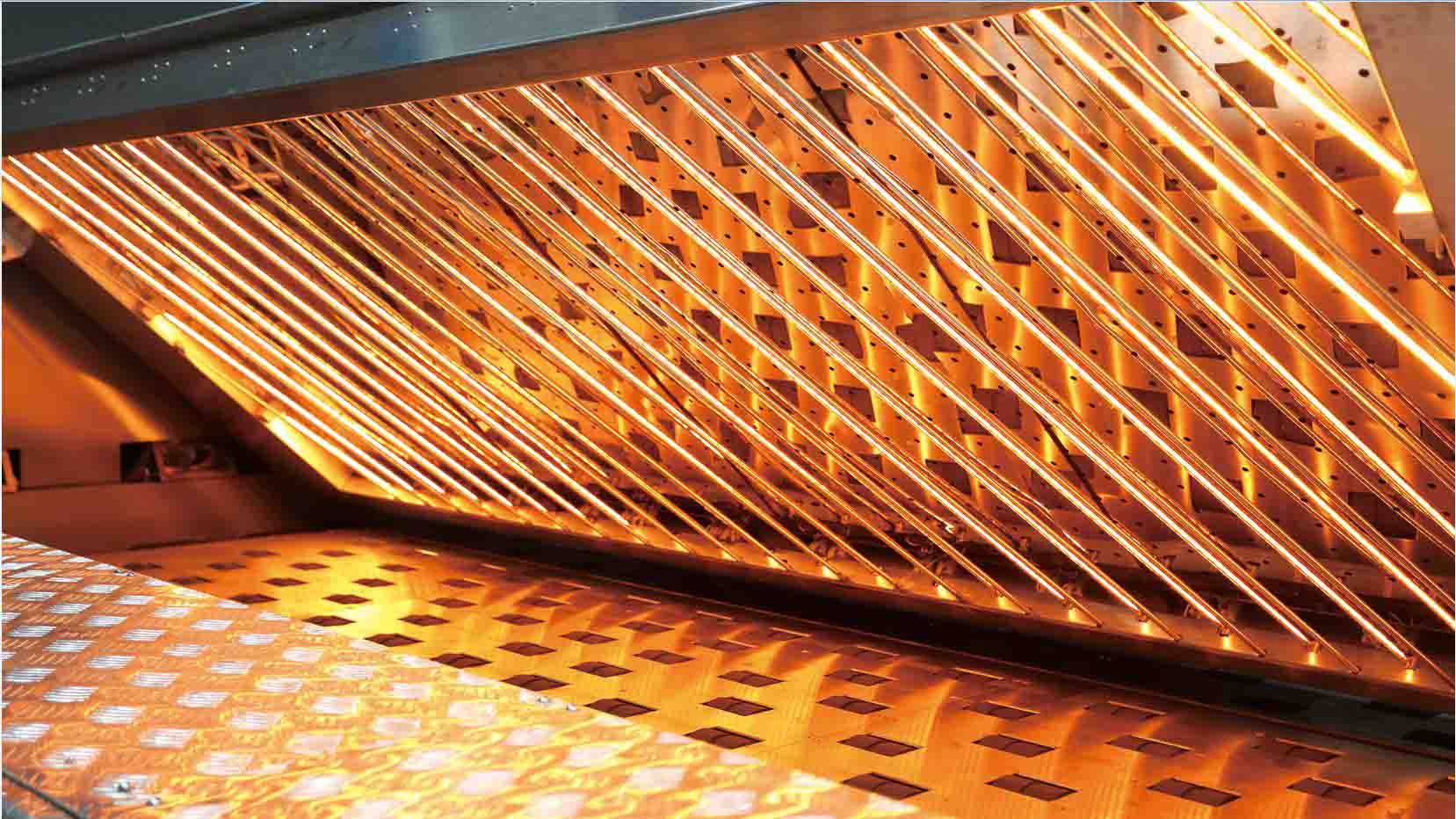

Dryer Unit ( Infrared dryer or UV dryer system as optional )

IR lamp is segmented control. So lamp could be set according to paperboard width to save power.

UV dryer makes UV coated paperboard surface to dry very quickly. So ink smear will not happen and also the machine speed improved with high quality product.

Slotter Unit ( Double creaser )

Die-cutter Unit ( Independent Servo Motor Drive )

Servo motor drive for the unit, no any vibration to the printer unit. So the printing register promised.

Anvil cylinder speed compensation achieved by adopting independent motor,the compensation scope is 5mm.

Die-Cutting register controlled by PLC with servo motor drive.

Micro-grinding system is available.(Optional)