High Speed Die-cutting Machine

1. T-ONE high speed die-cutting machine applied with original American SUN gear box: accurate paper feeding, error within +/-1mm,

stable performance and high running speed.

2. Original American SUN leading edge paper feeding platform for the die-cutting machine: the platform is CNC machined from the

whole cast aluminum material without deformation. Stable operation, accurate paper feeding, high running speed and durability.

- T-ONE

- Foshan,China

- Information

- Video

- Download

TD1600X2800 High speed flexo die-cutting machine

(roll to roll transfer)

Main Parameters

Model | TD920 | TD1224 | TD1228 | TD1426 | TD1628 | TD1632 | TD2236 | TD2242 | TD2636 |

Max. Speed(pcs/min) | 300 | 250 | 230 | 200 | 180 | 180 | 140 | 130 | 100 |

Max Feeding Size(mm) | 900×2000 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 | 1600×3200 | 2200×3600 | 2200×4200 | 2600×3600 |

Min Feeding Size(mm) | 260×600 | 320×600 | 320×600 | 420×600 | 450×600 | 450×600 | 500×700 | 500×700 | 500×700 |

Skip Feeding (mm) | 1200×2000 | 1500×2400 | 1500×2800 | 1700×2600 | 1900×2800 | 1900×3200 | 2500×3600 | 2500×4200 | 2800×3600 |

Max. Printing Area(mm) | 900×1960 | 1200×2360 | 1200×2760 | 1400×2560 | 1600×2760 | 1600×3160 | 2200×3560 | 2200×4160 | 2500×3560 |

Min. Slotting Reverse knife(mm) | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 360×95×360×95 | 360×95×360×95 | 360×95×360×95 |

Min. Slotting Normal knife(mm) | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 150×150×150×150 | 150×150×150×150 | 150×150×150×150 |

Slotting Depth (mm) | 250 | 300 | 300 | 350 | 400 | 400 | 700 | 700 | 700 |

Main Features:

● The TD series high-speed machine adopts the international advanced design concept, has passed the European CE certification, is designed and manufactured according to

the European and American manufacturing standards, and is designed and manufactured by Tai Yi's own many years of production experience.

● The transmission gear is imported, the gear is hardened and ground, and the Rockwell hardness is 60 degrees.

● Self-locking structure is adopted for the gap adjustment of transfer roller, impression roller, rubber roller and anilox roller.

● Independent computer control, can store frequently used orders, change orders quickly, easy to operate.

● Auto-zero, auto-reset.

Product Detailed

Feeder Unit

● Sun Automation Lead Edge Feeding System

● Dust Removal System

● Units Open and Close,Zeroning Sytem

Printer Unit

● Quick lock printing plate setting system on both R/L sides

● Transfer way: roll to roll

● Auto ink cleaning function

● Self-lock system for the gap adjustment between feeding rolls, pressing rolls, rubber roll and anilox roll.

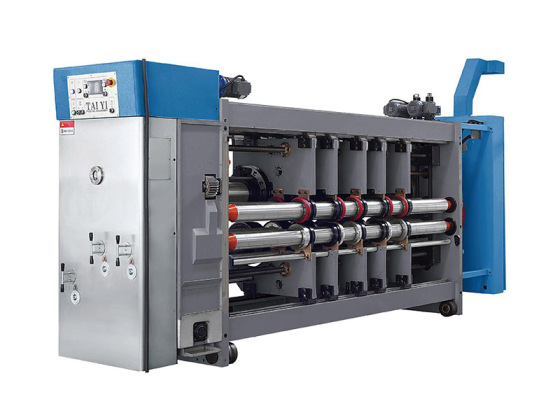

Slotter Unit

● Six Shafts, One Shaft with Front and Back Slotting Knife, Internal Gear Applied to Adjust Carton Height. Prevents Lubricant onto Paperboard.

● Lead Screw Matching with Liner Guide for Slotting Base Lateral Movement, More Flexible and Precise.

● Upper and Lower Base Coupled Movement, While Moving the Male and Female will be in the Same Line, Slotting Knife Prolonged.

● Pre-creaser, Creaser and Slotting Base Lateral Movement are PLC controlled and Motorized.

Die-cutter Unit

● 50mm transverse direction movement structure for anvil cylinder.

● Motorized gap adjustment between anvil cylinder and die cylinder.

● Self-lock system for gap adjustment.

● Independent motor used for the anvil cylinder speed compensation, the compensation range is 5.0mm.

● Anvil cover trimming system is applied to keep anvil cover surface flat and smooth.