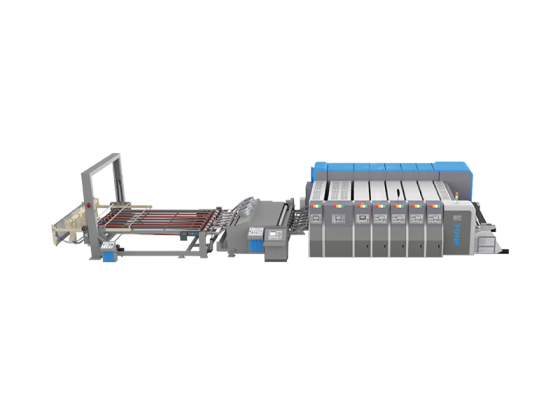

Vacuum Transferring Flexo Printing Machine

1. T-ONE flexo printing machine adopts PLC touch screen control, with automatic counting and other functions;

2. All drive rollers for T-ONE flexo printing machine are made of high-quality steel, after dynamic and static balance test, chrome-plated, polished; Hard grinding>60o Rockwell hardness

3. Original SUN automation feeding system applied to T-ONE flexo printing machines

- T-ONE

- Foshan,China

- Information

- Video

- Download

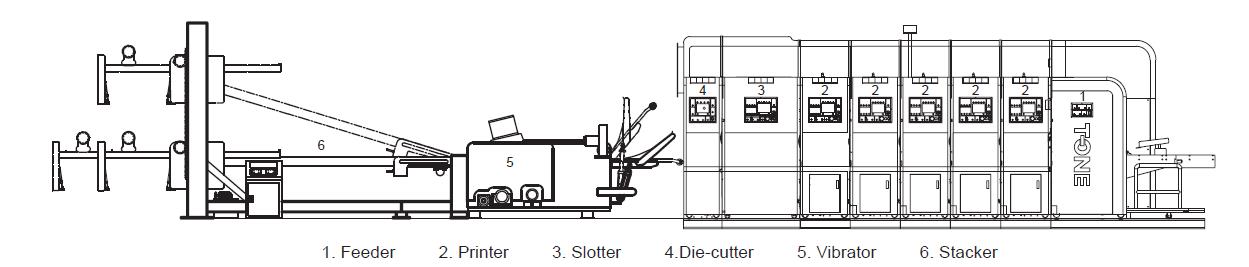

T-GC1400X2800 Vacuum Transferring Flexo Printing Machine

Main Parameters:

Model | T-GC618 | T-GC920 | T-GC924 | T-GC1224 | T-GC1228 | T-GC1428 | T-GC1628 | T-GC1632 | T-GC1636 |

Max. Speed(pcs/min) | 350 | 300 | 300 | 250 | 230 | 220 | 180 | 180 | 160 |

Max Feeding Size(mm) | 600×1800 | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 | 1400×2800 | 1600×2800 | 1600×3200 | 1600×3600 |

Min Feeding Size(mm) | 200×435 | 270×600 | 270×600 | 320×600 | 320×600 | 365×600 | 450×600 | 450×600 | 450×600 |

Skip Feeding (mm) | 800×1800 | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 | 1700×2800 | 1900×2800 | 1900×3200 | 1900×3600 |

Max. Printing Area(mm) | 600×1760 | 900×1960 | 900×2360 | 1200×2360 | 1200×2760 | 1400×2760 | 1600×2760 | 1600×3160 | 1600×3560 |

Min. Slotting Reverse knife(mm) | 180×55×180×55 | 240×65×240×65 | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 |

Min. Slotting Normal knife(mm) | 110×110×110×110 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 |

Slotting Depth (mm) | 200 | 250 | 250 | 300 | 300 | 350 | 400 | 400 | 400 |

Printer Unit with Vacuum Transfer

Ø Vacuum for paperboard transfer, ceramic-coated transfer wheel for increasing the friction and service life.

Ø Printing register adjustment is servo motor driven.

Ø Imported Doctor-blade inking system is available. (Optional)

Ø IR system for drying is available. (Optional)

Slotter Unit

A. Front and Back Slotting Knife is assembled on two shafts, Internal Gear Applied to Adjust Carton Height. Prevents Lubricant onto Paperboard.

Ø Solid chromed and ground steel creasing shaft.

Ø Pre-creaser to make paperboard not easily damaged while creasing.

Ø Upper creasing wheel covered by anvil ring, paperboard will not be damaged.

Ø Pre-creaser and creaser gap PLC control, range from 0-12mm.

B. Lead Screw Matching with Liner Guide for Slotting Base Lateral Movement, More Flexible and Precise.

Ø Solid chromed and ground steel for slotting shaft.

Ø Standard slotting knife width is 7mm.

Ø Center slotting knife is movable.

Ø Motorized slotting base gap adjust.

Ø Cam bearing applied for the impression roll working, wear reduced and run more stable.

C. Upper and Lower Base Coupled Movement, While Moving the Male and Female will be in the Same Line, Slotting Knife Prolonged.

D. Pre-creaser, Creaser and Slotting Base Lateral Movement are PLC controlled and motorized.

E. Protective Device Applied to Prevent Slotting Knife from Crashing when Carton box Height Adjusted.

F. Lead Screw Matching with Liner Guide for Slotting Base Lateral Movement, More Flexible and Precise.

G. Flap Cutting Knife could Cut 3-5 Ply Board with no Adjust.

H. Slotting Registration Adjust.

Ø Planetary gear structure.

Ø Slotting register and height of carton box are controlled by PLC and motorized.

Rotary Die-cutter Unit (Servo Drive Optional)