Automatic PE Corrugated Box Strapping Machine

1.The whole machine is operated by computer, can save common used orders, operation is fast and convenient, maintenance is easy.

2.Automatic multi points oil-lubricating refuel.

3.PE Tape Full automatic servo-drive double strapping, Can be inline the Auto fold gluer for strapping.

Can be inline the flexo printer folder gluer (FFG) for strapping

4.Can be inline the Automatic Stitcher for strapping.

5.Can be inline the multiple semi-auto stitcher for strapping.

6.Can be inline the multiple semi-auto folder gluer and stitcher for strapping

7.Can save the labor force (around 4-8 workers), reduce the effect of productivity due to the labor force. Save the using cost 5 times than the PP tape strapping per meter.

8.Strapping speed is 2 times faster than the traditional PP tape strapping machine.

- Information

Automatic PE Corrugated Box Strapping Machine

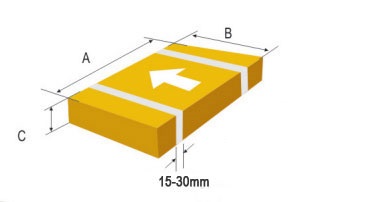

Strapping Size (A)

| 380-1400mm | |

Strapping Size (B)

| 250-1300mm | |

Strapping Size (C)

| 60-260mm | |

Strapping Size (D)

| 250-1000mm | |

Running Speed | 28±2 Bundle/min.(A Size 600mm,B Size 280mm) | |

Features | Orders or size changed is automatic adjustment; centralization lubrication; knot output section adopt servo control and drive | |

Strapping Material

| PE Tape(28# to 50#) | |

Machine Size

| 3000(L)x2500(W)x2100(H)mm | |

| Feeding Height | 800mm~1200mm(inline with folding guler machine) | |

Working Pressure

| 0.6Mpa | |

Working Voltage

| 3 Phase 380V | |

Total Power | 3.5kw | |

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more