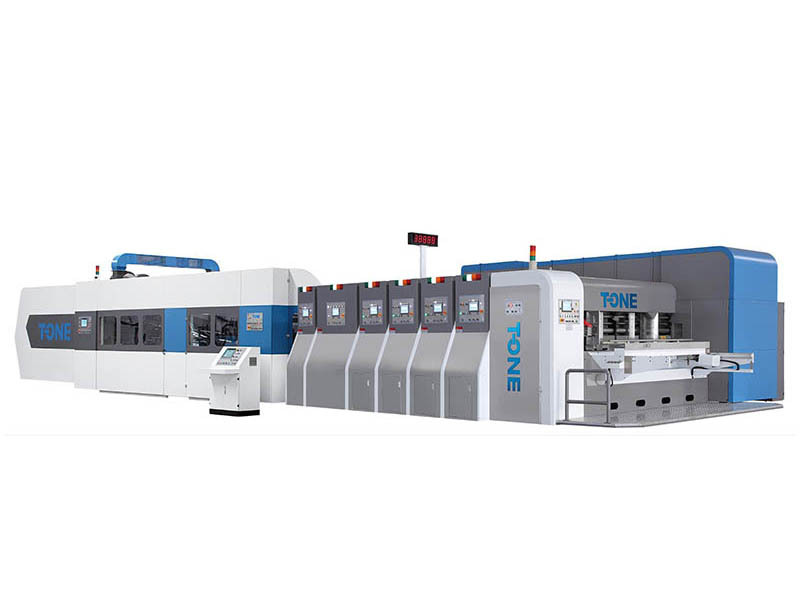

Corrugated Cardboard Box Folder Gluer Machine

T-ONE corrugated flexo folder gluer,one-stop intelligent packaging solution adopts high-end glue spraying system, precise glue spraying control, firm adhesion of carton

T-ONE folding gluer machine equipped with a new folding system, the gap adjustment precision is high, and the right angle is corrected.

Synchronous coordination of multiple sets of servo motors in the technical department of the folding gluer machine, accurate counting

- T-ONE

- Foshan,China

- Information

- Video

- Download

Corrugated Cardboard Box Folder Gluer Machine -FFG 2000

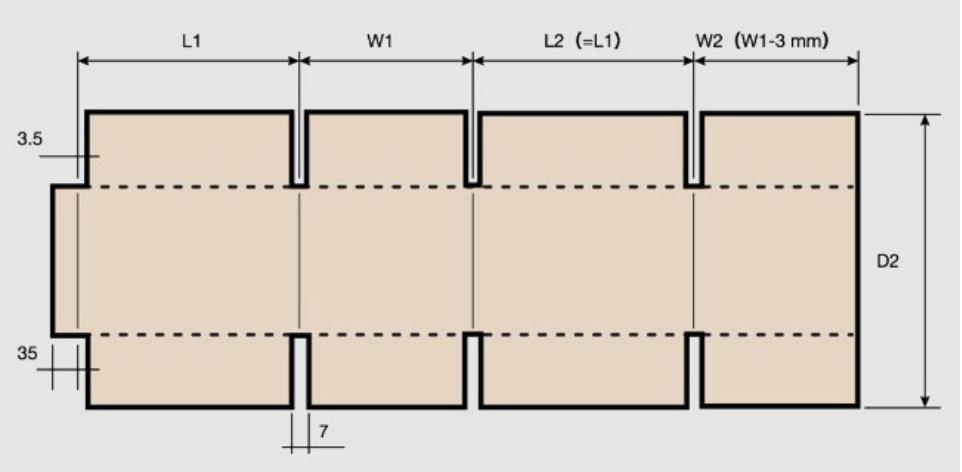

Main Parameter

Model | 1800 | 2000 | 2400 | 2800 | 3200 | |

Max Speed | 350pcs/min | 300pcs/min | 250pcs/min | 230pcs/min | 180pcs/min | |

Carton length(L2) | Max | 550 | 700 | 750 | 800 | 900 |

Min | 135 | 180 | 180 | 200 | 220 | |

Carton width(W1) | Max | 500 | 650 | 700 | 750 | 800 |

Min | 120 | 150 | 150 | 150 | 150 | |

L2 + W1 | Max | 870 | 1000 | 1200 | 1400 | 1560 |

Min | 285 | 330 | 335 | 350 | 370 | |

L2 :W1 | Max rate | 2:1 | 2:1 | 2:1 | 2:1 | 2.5:1 |

Carton width(D2) | Max | 600 | 900 | 1200 | 1200 | 1600 |

Min | 230 | 280 | 300 | 300 | 450 | |

Flap Width | 25-30 | 30~40 | 30~40 | 30~40 | 30~40 | |

Length | 15m |

Weight | 20.6 tons |

Power | 96KW (AC380V),50/60Hz,3 phase |

Air flow | 70/Litre(Air compressor 220V 1.5KW) |

Flute | A, B,C, AB, BC,EB |

Machine Speed

In case the technical improvement and changes without further notice, subject to contract

Product Detailed

A. Feeding Section

a. Computerized control, easy operation and order change.

b. Automatic adjustment of feeding baffles as per order.

c. Receive paperboard from printer.

d. Two more dust remover motor to clean cutting confetti.

e. 1400mm longer arms.

B. Gluing Section

a. Electric peristaltic pump used for glue pumping:Easy maintaining and lower cost.

b. Gluing position adjust by motor.

C. Folding Section

a. With new type folding structure: precise folding promises gap accurate.

b. The two folding arms are motorized and also will be adjusted automatically when you set the order in the computer.

c. Perforated main belts controlled by absorption blower to ensure smooth transition.

d. Strengthened rigidity of the folding rail: strengthened lower rail and vertical steel plates on both sides, and completely eliminate the vibration when the paperboard passes.

e. Folding belts speed on both sides is adjusted independently by independent motors as per different length and width.

f. Equipped with independent speed-adjusted motor shaping belts on back part of folding section to reduce scissor deviation.

g. Pressure of main belts on both sides, gap between upper and lower folding bridge are adjusted by independent motor.

h. Independent correction servo motor equipped on back part of lower folding bridge to avoid influence from main belt. Equipped with 25 correction wheels on each side.

i. Air cylinder applied on lower folding bridge for micro-adjustment to ensure shaping effect.

j. Independent motor for belt adjustment on lower folding bridge and independent flapping motor.

k. Four vacuum absorption blowers ( two on each side) for stronger absorption.

l. Independent servo motor applied to adjust both sides of folding bridge.

m. Upped and lower folding arm moved by screw, upper and lower folding bridge moved synchronously.

n. Linear applied on both sides of feeding and flapping to ensure stabler movement.

D. Counter Ejector Section

a. Paperboard transit smoothly at high speed.

b. Accurate quantity counting of boxes and eject bundle of boxes with several servo motor control.

c. Strong fan installed on the top of counter ejector to avoid boxes inclined, and the fan mouth direction could be adjusted

d. All kinds of glued cartons is ensured stable and smooth transition.

e. Protection doors are automatically locked when folder gluer is running to ensure operation safety.

f. Independent motor applied for counter ejector movement, matched with screw and linear.

g. Racks applied for arms movement.

h. Press blower and rubber plates is added.

i. Press servo motor is applied on counter ejector section.

E. Control Panel

a. HMI color touch screen for setting and also for false alarm.

b. With remote control function.

Speed Limit Diagram

1)10pcs/bundle Scale:pcs/min

width Speed | 110 | 125 | 140 | 155 | 170 | 185 | 200 | 215 | 230 | 245 | 260 | 275 | 300 | 325 | 350 |

900 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ | ╳ | ╳ | ╳ |

800 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ | ╳ | ╳ |

700 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ | ╳ |

600 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ |

500 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ |

400 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ |

280 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ |

260 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ |

○ | Feasible | △ | Theoretically feasible | ╳ | Not Available |

2) 20pcs/bundle Scale:pcs/min

width Speed | 110 | 125 | 140 | 155 | 170 | 185 | 200 | 215 | 230 | 245 | 260 | 275 | 300 | 325 | 350 |

900 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ | ╳ |

800 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ | ╳ |

700 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ |

600 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ |

500 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ |

400 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

280 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ |

260 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | ╳ | ╳ |

○ | Feasible | △ | Theoretically feasible | ╳ | Not Available |

▲SPECIAL NOTES

a. Speed restriction occurs in the following cases:

b. Feeding length (H dimension) and piled (batch) blanks;

Operating conditions, such as:

a. Sheet flat

b. Printing area and state

c. Air temperature

d. With/without water repellency or degree of water repellency

e. Die-cutting shape

f. When feeding length (H dimension) of the blank is long or depth of the box is deep, the operating

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more