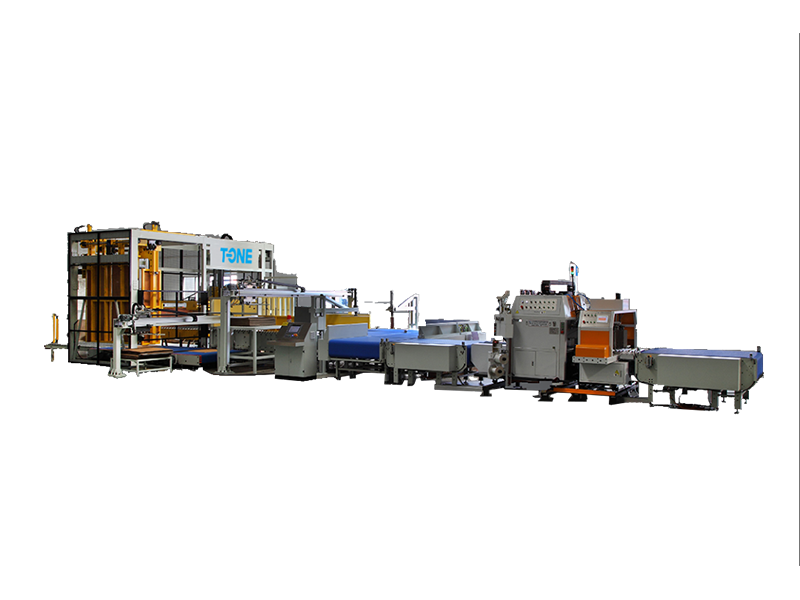

Full Automatic Palletizer Machine

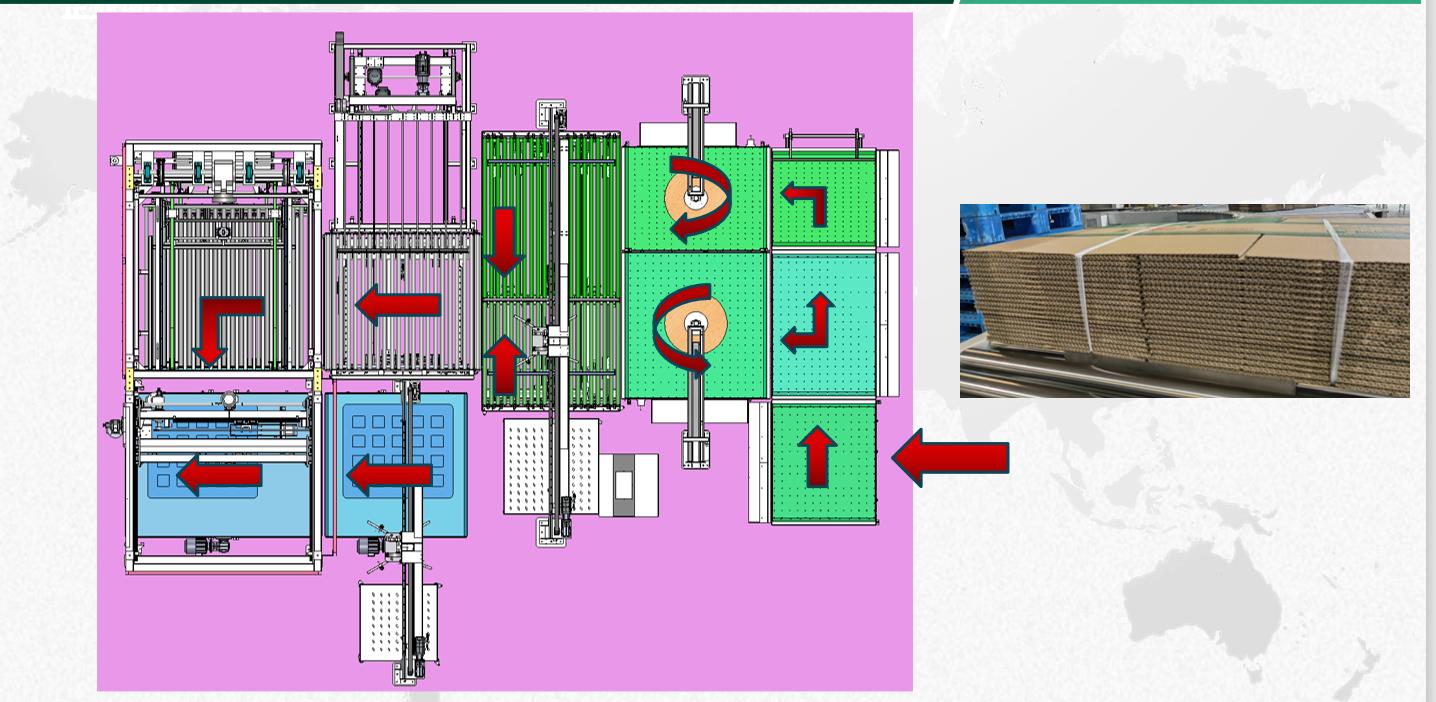

T-ONE automatic palletizer machine with high output and high efficiency, breaking through the upper limit of the industry, up to 28-30 packs of paper per minute.

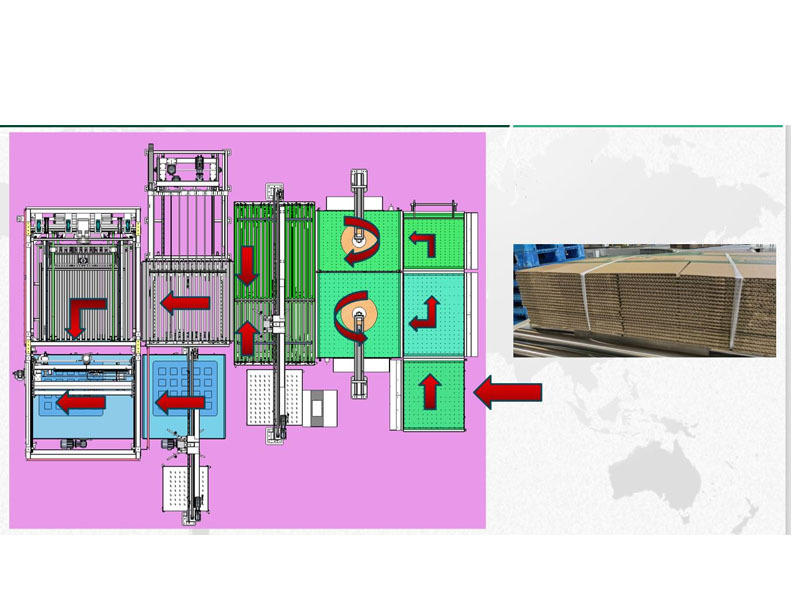

Five automatic rotating tables are used to T-ONE automatic palletizer to adapt to various box types and effectively prevent cardboard damage and the palletizer equipped with a flapping device to ensure neat stacking

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-SK Full Automatic Palletizer Machine

Main Features:

The whole machine control system adopts famous international brand.

Five turning tables for different carton types

Automatic robot for padding

Three-layer stacking section for large size carton

The stacking section equipped with flapping device

Automatic pallet insert(Optional)

When pallet not used, then could choose robot inserting paperboard pad

Main Parameters:

| Max speed | 30 bundles/min |

| Max bundle size | 1600x1400mm |

| Min bundle size | 300x350mm |

| Max stacking height | 1800mm |

Product Detailed:

T-ONE full automatic palletizer machine used in the packaging industry is to arrange the packed cartons in a certain order for automatic stacking,

which can be stacked in multiple layers, and then pushed out for easy transportation to the warehouse for storage. T-ONE automatic palletizer

realizes intelligent operation and management, which can greatly reduce the labor and labor intensity, and at the same time, the palletizer

has a good protection for the items, with dustproof, moisture-proof, waterproof, sunscreen and other protective functions, and prevents

the items from being damaged during transportation. wear, etc.

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more