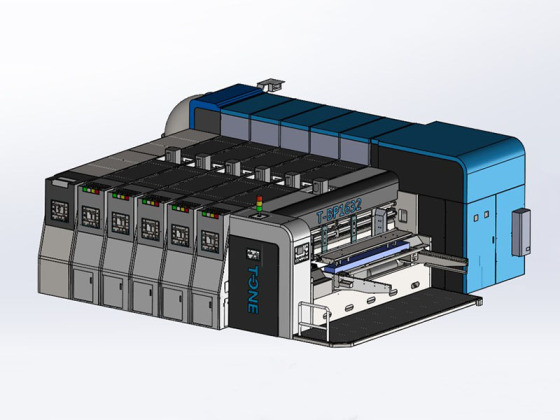

Automatic Carton Box Bottom Printing Machine

The conveying roller, embossing roller, rubber roller, anilox roller, large roller shaft head and bearing of the whole T-ONE automatic carton box bottom printing machine are upgraded by two grades to improve the life of the equipment and reduce the maintenance cost. The thickness of the wall panel of the whole machine is 70MM

The automatic carton box printing machine is adopted with the International advanced design ideal, with European-American industrial Criterion and Taiyi's Manufacturing experience with CE Certified. It fully reflects printing zero-deterioration; low water pollution; high quality, high stable performance and totally improves machine service life, T-ONE automatic carton box printing machine is a truly energy conservation, environment protection and low consumption equipment.

- T-ONE

- Foshan,China

- Information

T-BP900X2000 Automatic Carton Box Printing Machine

(Movable type,bottom printing,vacuum transfer)

Main Parameters:

Model | T-BP920 | T-BP1224 | T-BP1632 |

Max Speed(Sheet/min) | 300 | 250 | 160 |

Max Feeding Size(mm) | 900x2000 | 1200x2400 | 1600x3200 |

Min.Feeding Size(mm) | 300x600 | 320x600 | 450x600 |

Skip Feeding Size(mm) | 1100x2000 | 1500x2400 | 1900x3200 |

Max Printing Size(mm) | 900x1960 | 1200x2360 | 1600x3160 |

Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 |

Min.Slotting/Reverse Knife(mm) | 240x65x240x65 | 260x65x260x65 | 260x65x260x65 |

Min.Slotting/Normal Knife(mm) | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 |

Slotting Depth(mm) | 250 | 300 | 400 |

Product Detailed:

1) Feeder Unit

● Continuous or skip feeding is available.

●Lead edge feeder with four wheel-shafts and strong vacuum pressure for precise and stable feeding.

● Electronically adjusted variable feed stroke to reduce the pressure on the feed roll.

● Variable frequency drive control of the vacuum blower fan for increased or decreased vacuum suction to match different sizes of paperboard.

● Dual durometer No-crush Feed Roll to reduce flute damage and for extended feed roll life.

● The machine also offers a dust removing system with both a strong bush and air vacuum that can be adjusted by section according to the dimension of the paperboard.

● Manual adjustment of the Feed Roll caliper as standard. As optional this can be upgraded to Automatic PLC control with digital readout.

● Automatic PLC set up of the Feed Guides and Backstop Assembly for quick set ups.

● As an added safety feature, the main motor is protected from activation when the units are not fully closed and locked.

2) Printer Unit (bottom)

● Available with the Matthews Plate mounting systems each with lateral adjustment of the print cylinder

●The printing plate’s register is digitally controlled by the motor and PLC.

●The printing plate’s transverse register is also digitally controlled by the motor and PLC (+10mm).

●The caliper of the impression roll is also digitally controlled by the motor and PLC.

● The caliper of the inking roll and anilox roll is adjusted by a self-locking system.

● The caliber of the inking roll and anilox roll is also controlled by the motor and PLC (optional).

● A fixed device for the printing register and brake for the electromagnetic clutch is used when the unit is opened. Upon closing the unit, the positions are precisely restored so the unit is ready for production without adjustment.

●The machine also allows for automatic ink washing which improves ink recollection.

3) Slotter unit (Double creaser)

● An internal gear drive adjusts the height of the carton box and prevents the lubricant oil from splitting or leaking onto the paperboard.

● The slotting register and height of the carton box are digital controlled by the motor and PLC.

●The slotting boss moves along linear guides driven by lead screws so movement becomes more flexible and precise.

● The movement of the upper boss and lower boss are linked so the two knives stay aligned during movement, which is helpful to prolong their service life.

●The slotting boss’s caliper is controlled by the motor and PLC.

● A protective device prevents the slotting knife from crashing when height of the carton box is adjusted.

● A protective device (both electronically and mechanically) prevents the slotting boss from crashing into each other when the slotting boss starts transverse movement.

●The structure of the angle knives can cut 3-layer or 5-layer paperboard without adjustment.

● Hand hole-punching dies can also be used.

● Paperboard is not broken easily after creasing by first pre-creasing the roll prior to the second creasing.

● The pre-creasing roll, creasing roll, and boss’s transverse movement are digitally controlled by the motor and PLC.

●The caliper of the pre-creasing and creasing wheels are adjusted with a self-locking device.

●The caliper of the pre-creasing and creasing rolls is digitally controlled by the motor and PLC (optional).

4) Rotary Die-Cutter unit

● Side to side oscillation of anvil cylinder( 50mm).

● The die cylinder transverse movement can prolong the service life of anvil cover.

● Die-cutting register is controlled by motor and PLC.

● The die-cutting cylinder lateral register is controlled by motor and PLC, range about±10mm.

● Motorized caliper adjustment between anvil roll and die cylinder.

● Self-locking system is adopted on pulling rolls.

●Anvil roll speed controlled by frequency motor