Eco-friendly Bottom Box Printing Machine

Dedicated computer controls are provided to T-ONE eco-friendly bottom box printing machine and orders can be stored and recalled by the local PLC controls.

The bottom box printing machine also allows for quick and easy setup of orders and an increased level of convenience of operation.

- T-ONE

- Foshan,China

- Information

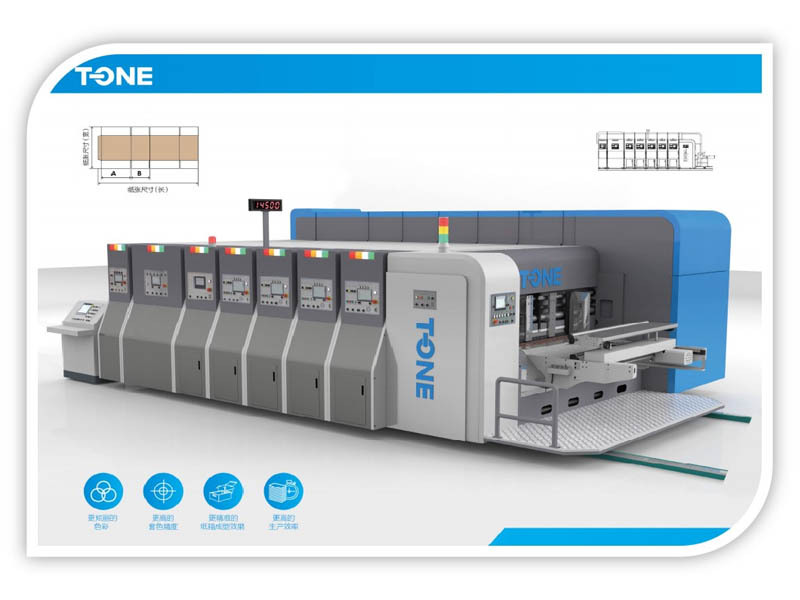

T-BP1200X2400 Eco-friendly Bottom Box Printing Machine

(Movable type,bottom printing,vacuum transfer)

Main Parameters:

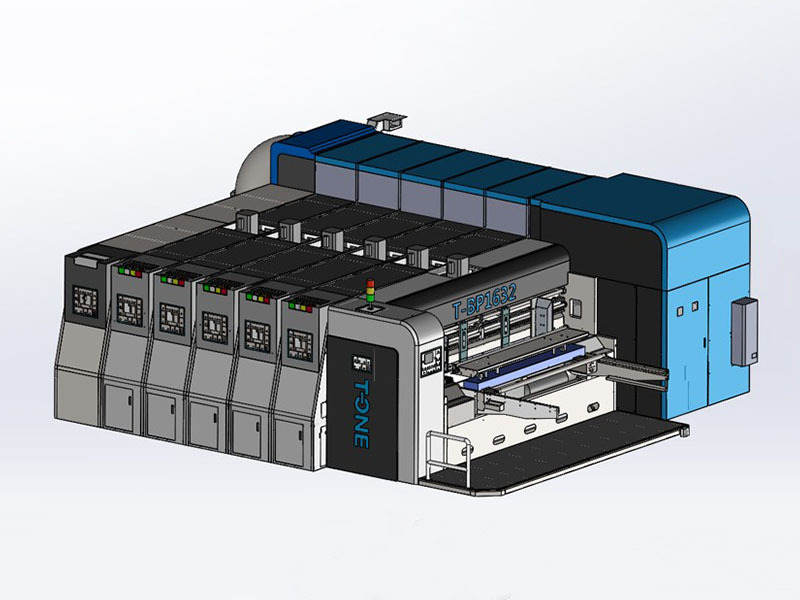

Model | T-BP920 | T-BP1224 | T-BP1632 |

Max Speed(Sheet/min) | 300 | 250 | 160 |

Max Feeding Size(mm) | 900x2000 | 1200x2400 | 1600x3200 |

Min.Feeding Size(mm) | 300x600 | 320x600 | 450x600 |

Skip Feeding Size(mm) | 1100x2000 | 1500x2400 | 1900x3200 |

Max Printing Size(mm) | 900x1960 | 1200x2360 | 1600x3160 |

Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 |

Min.Slotting/Reverse Knife(mm) | 240x65x240x65 | 260x65x260x65 | 260x65x260x65 |

Min.Slotting/Normal Knife(mm) | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 |

Slotting Depth(mm) | 250 | 300 | 400 |

Machine Brief Introduction

●The whole machine is designed and manufactured according to the high requirements with the reliable and safety function.

●New outlook of industrial design.

●Quality of all transition shafts, impression rollers, rubber rollers, anilox rollers, Cylinder spindle heads and bearings are two grades higher to ensure longer service life and reduce maintenance cost.

●All frame wall thickness is 70MM for more steady operation.

●Adopts spray lubrication, and the oil tank adopts automatic balancing device to reduce maintenance

●Positioning pins are used between the printing unit to ensure stable lateral accuracy

●Precision gear reducer adopted to ensure the long-lasting precision and stability of the product

●The whole machine adopts the cam bearing to replace the copper cross slider, which is maintenance-free.

●Built-in bridge line, for more concise appearance

●Siemens system is applied. Main components are imported with remote control module to ensure quality and stability.

●Malfunctions can be diagnosed by remote control system. Maintenance and trouble-shooting will be more efficient.

●Driving shafts are made of high-quality steel, chrome plated, and surface ground.

●Imported gears are hardened and ground (hardness>60HRC).

●Keyless connecting ring applied, to reduce center wear, enlarge virtual position, maintain long-term printing registration

●Auto zero, auto reset.

●Lubrication oil leveled system to keep all units lubrication oil in the same level.

●Repeat orders can be stored and recalled by PLC control for fast order set-up and easy operation. 9999 orders could be saved. Dedicated computer control desk is provided

●Every unit is also equipped with an emergency stop switch for increased safety. The machine operator, working inside each unit can stop the unit from moving at any time.

●All units of the machine can be separated automatically or manually, an audible alarm sounds during the opening and closing for safe operation.

●A large-screen digital display installed, the operator can easily see the running speed of the machine in different directions.

●All gaps setting controlled by PLC.

●Movable dust removal device in Feeder Unit.