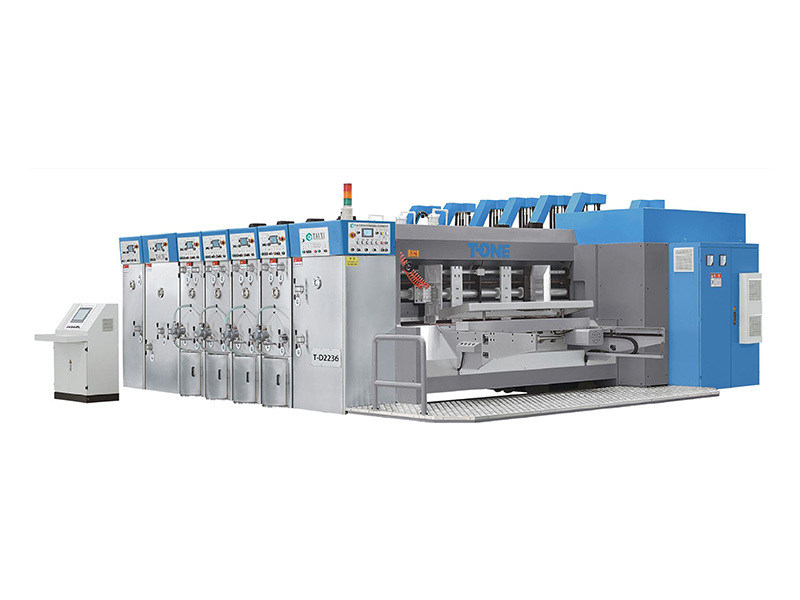

High Speed Flexo Rotary Die-cutter

T-ONE high speed flexo rotary die-cutter with self-locked system for all roller gap adjustments.and can store different orders by independent computer control table

- T-ONE

- Foshan,China

- Information

- Video

- Download

TD1200X2400 High Speed Flexo Rotary Die-cutter

(Roll to roll transfer)

Main Parameters

Model | TD920 | TD1224 | TD1228 | TD1426 | TD1628 | TD1632 | TD2236 | TD2242 | TD2636 |

Max. Speed(pcs/min) | 300 | 250 | 230 | 200 | 180 | 180 | 140 | 130 | 100 |

Max Feeding Size(mm) | 900×2000 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 | 1600×3200 | 2200×3600 | 2200×4200 | 2600×3600 |

Min Feeding Size(mm) | 260×600 | 320×600 | 320×600 | 420×600 | 450×600 | 450×600 | 500×700 | 500×700 | 500×700 |

Skip Feeding (mm) | 1200×2000 | 1500×2400 | 1500×2800 | 1700×2600 | 1900×2800 | 1900×3200 | 2500×3600 | 2500×4200 | 2800×3600 |

Max. Printing Area(mm) | 900×1960 | 1200×2360 | 1200×2760 | 1400×2560 | 1600×2760 | 1600×3160 | 2200×3560 | 2200×4160 | 2500×3560 |

Min. Slotting Reverse knife(mm) | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 360×95×360×95 | 360×95×360×95 | 360×95×360×95 |

Min. Slotting Normal knife(mm) | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 150×150×150×150 | 150×150×150×150 | 150×150×150×150 |

Slotting Depth (mm) | 250 | 300 | 300 | 350 | 400 | 400 | 700 | 700 | 700 |

Feeder Unit Featrues:

A. Sun Automation Lead Edge Feeding System

●With three shafts and strong vacuum suction. So the feeding precise and stability are promised for both high speed and low speed.

● Feeding stroke could be adjusted to reduce feeding roller impression.

● Frequency converter control the vacuum to match different size paperboard.

● High stability with high speed, less noise and variation.

● Left and right side guides are PLC controlled and motorized.

● Motorized backstop forward and backward movement.

● Continuous or skip feeding is available with counter.

B. Dust Removal System

● Dust removal system with several brushes and segmented vacuum sheet cleaner.

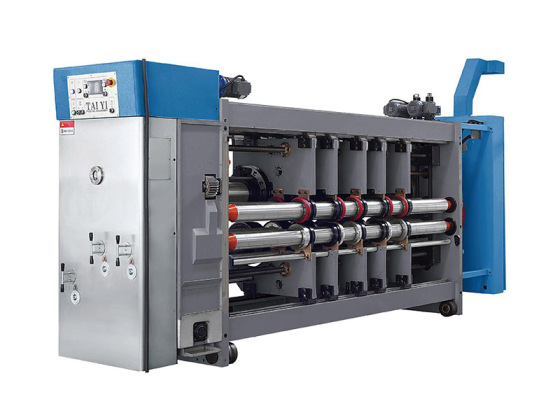

C. Upper and Lower Feeding Roll

● Upper feeding roll wrapped with wear resistant rubber.

● Lower feeding roll surface knurled and chrome-plated.

● Self-locked system applied for adjusting feeding roll gap, range is 0-12mm.

●Cam bearing applied for impression roll power transmission, wearing reduced and also transfer more stable.

D. Units Open and Close, Zeroing System

● With clutch for the machine open and close to avoid damage the machine while in moving.

● Main motor protected from starting up when units are not completely closed and locked.

● Encoder applied for all units with zeroing function.

● Zeroing function used for sample making, generally speaking two paperboards are enough.