High Speed Printer Slotter Machine

1.T-ONE printer slotter machine with CE certificated ,designed with advanced concept, made according to European standards with

Tai Yi many year experience in producing machines.

2.The hardened micro-grinded driving gears of T-ONE printer slotter machine are imported with HC>60°.

3.Self-locked system is applied for all roller gap adjustments.Independent computer control table is able to store different orders,

quick order changes and easy for operation.

4.T-ONE printer slotter machine with automatic zero setting and reset function.

- T-ONE

- Foshan,China

- Information

- Video

- Download

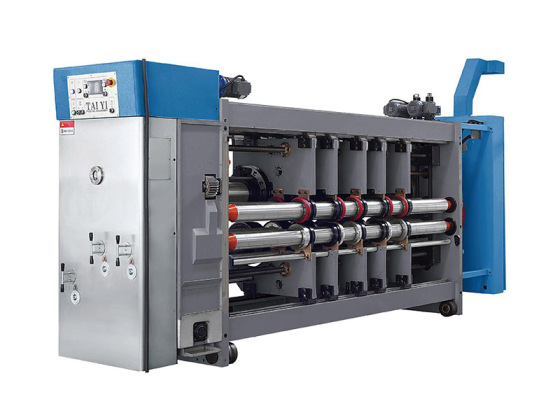

TD900X2000 High Speed Printer Slotter Machine

(roll to roll transfer)

Main Parameters

Model | TD920 | TD1224 | TD1228 | TD1426 | TD1628 | TD1632 | TD2236 | TD2242 | TD2636 |

Max. Speed(pcs/min) | 300 | 250 | 230 | 200 | 180 | 180 | 140 | 130 | 100 |

Max Feeding Size(mm) | 900×2000 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 | 1600×3200 | 2200×3600 | 2200×4200 | 2600×3600 |

Min Feeding Size(mm) | 260×600 | 320×600 | 320×600 | 420×600 | 450×600 | 450×600 | 500×700 | 500×700 | 500×700 |

Skip Feeding (mm) | 1200×2000 | 1500×2400 | 1500×2800 | 1700×2600 | 1900×2800 | 1900×3200 | 2500×3600 | 2500×4200 | 2800×3600 |

Max. Printing Area(mm) | 900×1960 | 1200×2360 | 1200×2760 | 1400×2560 | 1600×2760 | 1600×3160 | 2200×3560 | 2200×4160 | 2500×3560 |

Min. Slotting Reverse knife(mm) | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 360×95×360×95 | 360×95×360×95 | 360×95×360×95 |

Min. Slotting Normal knife(mm) | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 150×150×150×150 | 150×150×150×150 | 150×150×150×150 |

Slotting Depth (mm) | 250 | 300 | 300 | 350 | 400 | 400 | 700 | 700 | 700 |

Product Detailed

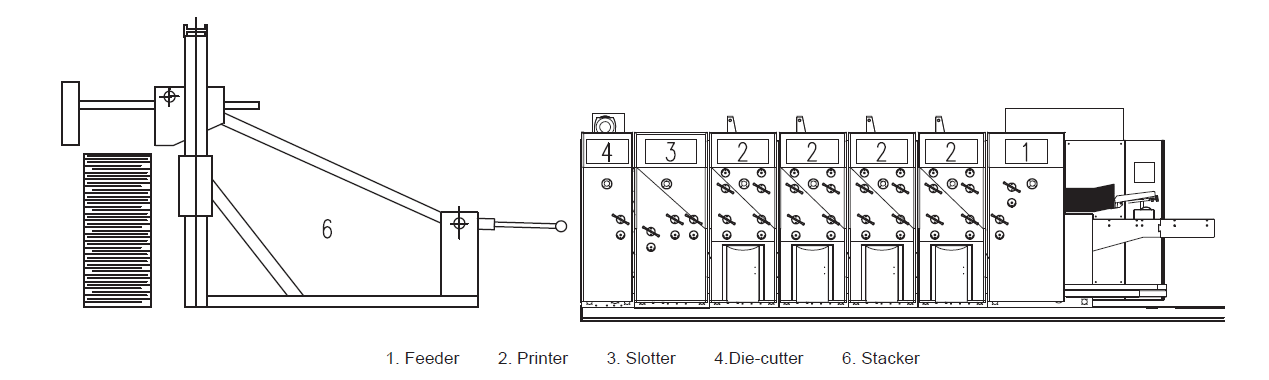

Feeder Unit

Continuous or skip feeding is available with counter.

Lead Edge Feeder with strong vacuum for precise and stable feeding.

Dust removal system with brushes and segmented vacuum sheet cleaner.

Self-locked system is applied for adjusting feeding roll gap.

Printer Unit

Quick lock printing plate setting system on both R/L sides to achieve precise alignment.

Roll to roll paperboard transfer.

Auto cleaning function to promise ink recycle throughly.

Self-lock system is adopted for adjusting the gap between feeding rolls,

pressing rolls, rubber roll and anilox roll.

Doctor-blade inking system is available. ( optional)

Slotter Unit

Single shaft with double slotting knives. Internal gear structure applied for adjusting carton box height, and prevents the lubricant oil from spilling or

leaking onto the paperboard.

Lead screw and guide rail matched for slotting base moving, which makes the movement much more flexible and precise.

Transversal movement of the pre-creasing roll, creasing roll and slotting base are motorized and PLC control.

Self-lock structure for the gap between male and female slotting knife applied.

A protective device applied to prevent the slotting knife from crashing when the height of the carton box is adjusted.

Flap cutting knife can cut 3 and 5 ply paperboard with no adjustment, easy to operate.

Die-cutter Unit

50mm transverse direction movement structure for anvil cylinder.

Motorized gap adjustment between anvil cylinder and die cylinder.

Self-lock system for gap adjustment.

Independent motor used for the anvil cylinder speed compensation, the compensation range is 5.0mm.

Anvil cover trimming system is applied to keep anvil cover surface flat and smooth.

Vibrator & Auto Stacker

Cleaning section adopts independent motor. There are three vibrating points on vibrating shaft to fasten the vibrating frequency

in this high speed printer slotter machine.

Vibrating belts, which controlled by independent speed motor, adopting wrinkled imported belts that protect paperboard from damage.

Cleaning section back-end adopts air blower and brush devices, which also help to shake the wastepaper off and clean completely.

The connection arm can be manual or automatic operated.

Air compressed sheet catching arm: when the paperboard piled up to the set height, the catching arm will stretch out automatically to hold the paperboard.

Tension of the transfer belt at the connection arm can be adjusted individually, no equal length restriction.

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more