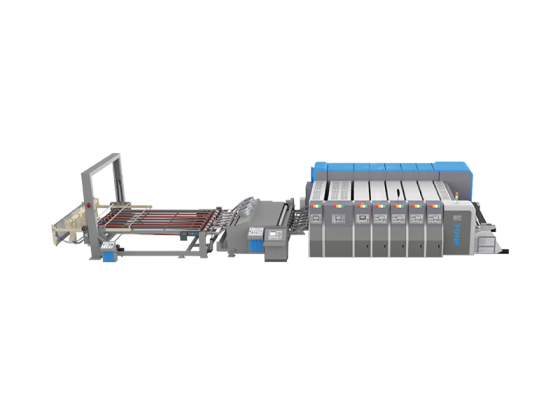

Vacuum Transfer Corrugated Box Printing Machine

T-ONE corrugated box printing machine with PLC control system with touch screen control,is able to save orders, quick order shift.

All electronic and pneumatic components are made according to European standards.T-ONE corrugated box printing machines are with CE certifications

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-GC1600X3200 Vacuum Transfer Corrugated Box Printing Machine

Main Parameters:

Model | T-GC618 | T-GC920 | T-GC924 | T-GC1224 | T-GC1228 | T-GC1428 | T-GC1628 | T-GC1632 | T-GC1636 |

Max. Speed(pcs/min) | 350 | 300 | 300 | 250 | 230 | 220 | 180 | 180 | 160 |

Max Feeding Size(mm) | 600×1800 | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 | 1400×2800 | 1600×2800 | 1600×3200 | 1600×3600 |

Min Feeding Size(mm) | 200×435 | 270×600 | 270×600 | 320×600 | 320×600 | 365×600 | 450×600 | 450×600 | 450×600 |

Skip Feeding (mm) | 800×1800 | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 | 1700×2800 | 1900×2800 | 1900×3200 | 1900×3600 |

Max. Printing Area(mm) | 600×1760 | 900×1960 | 900×2360 | 1200×2360 | 1200×2760 | 1400×2760 | 1600×2760 | 1600×3160 | 1600×3560 |

Min. Slotting Reverse knife(mm) | 180×55×180×55 | 240×65×240×65 | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 |

Min. Slotting Normal knife(mm) | 110×110×110×110 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 |

Slotting Depth (mm) | 200 | 250 | 250 | 300 | 300 | 350 | 400 | 400 | 400 |

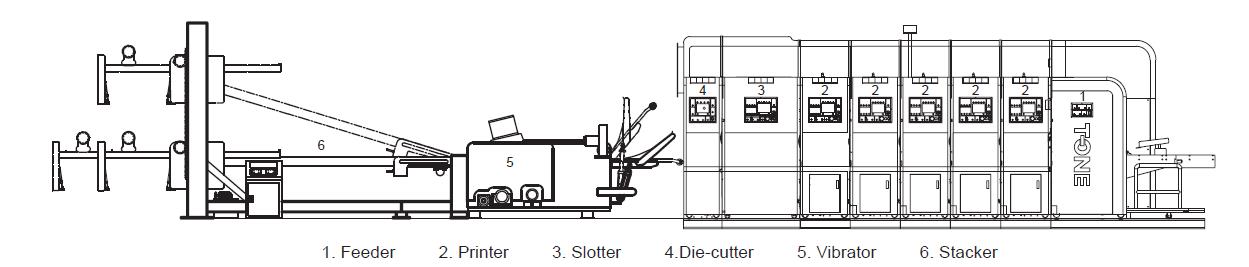

Product Detailed:

Feeder Unit-SUN Automation Lead Edge Feeding System

Printer Unit with Vacuum Transfer

Dryer Unit ( Independent infrared dryer as optional )

Slotter Unit -Double Creaser

Rotary Die-cutter Unit (Servo Drive Optional)

Vibrator & Auto Stacker

Cleaning section adopts independent motor. There are three vibrating points on vibrating shaft to fasten the vibrating frequency.

Vibrating belts, which controlled by independent speed motor, adopting wrinkled imported belts that protect paperboard from damage.

Cleaning section back-end adopts air blower and brush devices, which also help to shake the wastepaper off and clean completely.

The connection arm can be manual or automatic operated.

Air compressed sheet catching arm: when the paperboard piled up to the set height, the catching arm will stretch out automatically to hold the

paperboard.

Tension of the transfer belt at the connection arm can be adjusted individually, no equal length restriction.