Fixed Full Servo Cardboard Printing Machine

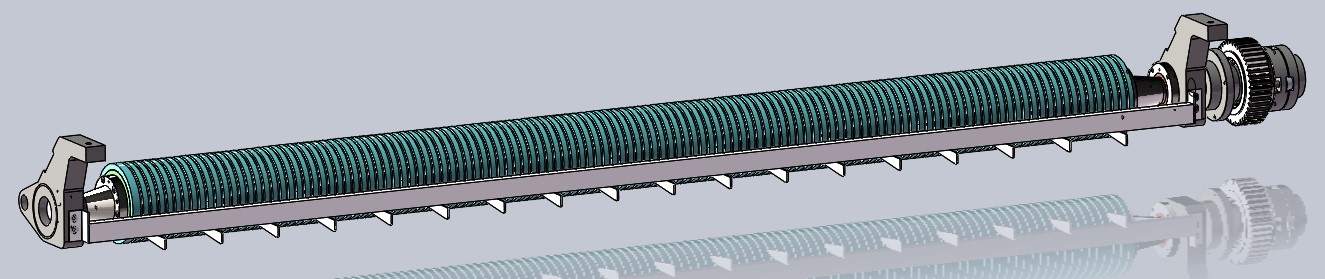

1. T-ONE fixed full servo cardboard printing machine, all rollers are made of high-quality steel, plated with hard chrome and surface ground;

2. Each unit of the cardboard printing machine is fixed with vacuum transfer chamber , printing registration is controlled by servo, and infrared (IR) or ultraviolet (UV) drying device can be selected. Realize high-point precision printing;

3. The fixed full servo cardboard printing machine is controlled by touch screen PLC, full-servo non-stop plate change, can store and recall the order data, change orders quickly, easy to operate; remote control can be realized through the network, troubleshoot equipment quickly

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-FS1200X2800 Fixed Full Servo Cardboard Printing Machine

(Fixed structure,servo drive,top printing,vacuum transfer)

Main Parameters:

Model | T-FS920 | T-FS924 | T-FS1224 | T-FS1228 |

Max. Speed(pc/min) | 350 | 350 | 350 | 300 |

Max Feeding Size(mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 |

Min Feeding Size(mm) | 300×600 | 300×600 | 350×600 | 350×600 |

Skip Feeding(mm) | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 |

Max. Printing Size(mm) | 900×1950 | 900×2350 | 1100×2350 | 1100×2750 |

Machine Brief Introduction

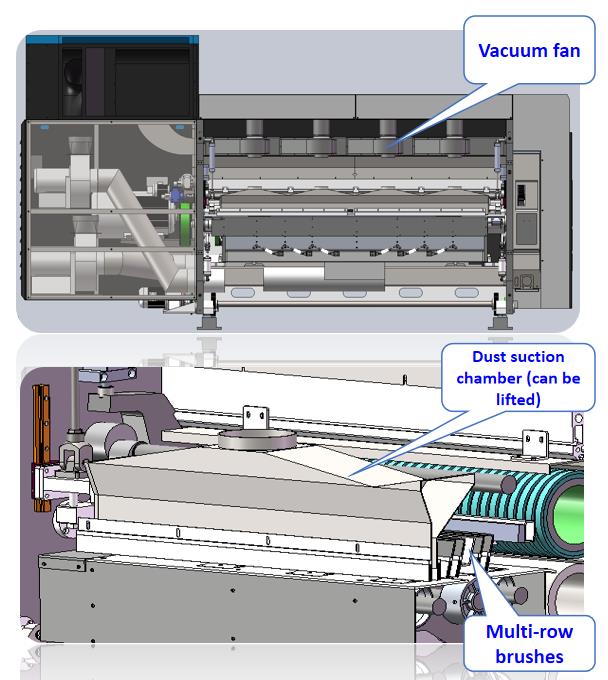

※ The overall suction device can be raised by about 150mm, which is convenient for maintaining and brush change.

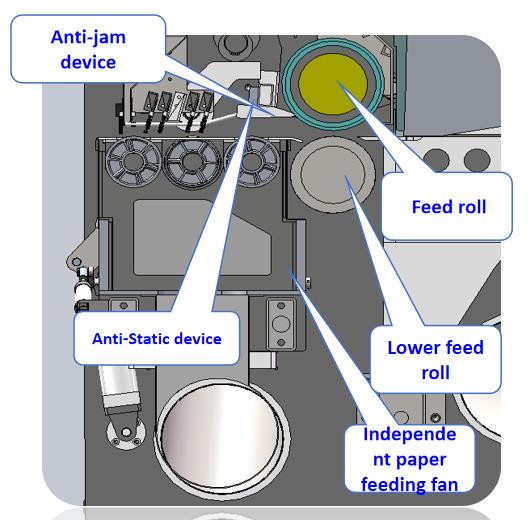

※ Multi-row brush and anti-static system, and anti-jam device.

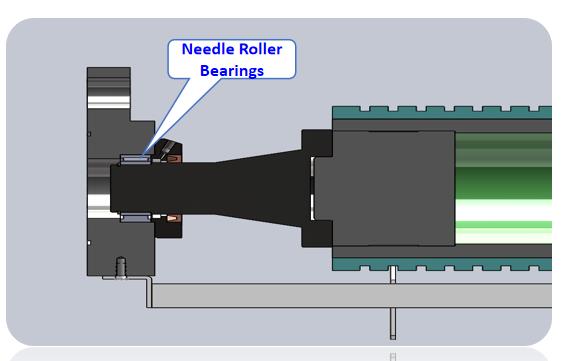

※ Cross-sectional view of the motor side: the shaft journal is fixed with needle bearing, which is convenient for the feeding rubber roll change. The replacement of the rubber roll does not require removing the oil tank gear, which is more convenient to replace.

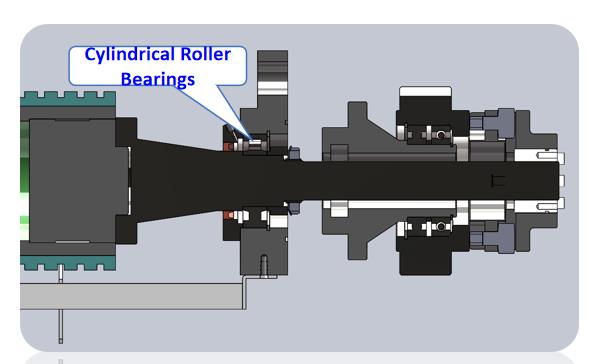

※ Cross-sectional view of the end of the oil tank surface: the installation bearing of the shaft head at this end is still a cylindrical roller bearing.

※ The rubber roller adjusts the upper and lower heights, and is automatically adjusted by an independent motor drive, and the paper jam device also goes up and down together to ensure smooth paper feeding.

※ Quick printing plate change (optional full-servo non-stop plate change), quickly correct the inclination generated when the plate is fixed, and reach the correction range.

※The whole process with vacuum trasnfer, high over-lapped printing accuracy.

※ The unit is widened to help the ink dry and ensure the over-lapped printing accuracy (Optional: small infrared drying device).

※ Independent servo motor drive with safety performance:

1. Driven by servo motor of anilox roller.

2. Printing cylinder servo motor drive.

3. Vacuum box servo motor drive.

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more