Servo Drive Fixed Corrugated Printing Machine

T-ONE servo drive fixed corrugated printing machine,fully servo driven, full line with PLC control, non-stop for printing plate change. Order data can be stored in the servo drive corrugated printing machine, order change is very quick and operation so friendly.

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-FS900X2000 Servo Drive Fixed Corrugated Printing Machine

(Servo drive,fixed structure,top printing,vacuum transfer)

Main Parameters:

Model | T-FS920 | T-FS924 | T-FS1224 | T-FS1228 |

Max. Speed(pc/min) | 350 | 350 | 350 | 300 |

Max Feeding Size(mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 |

Min Feeding Size(mm) | 300×600 | 300×600 | 350×600 | 350×600 |

Skip Feeding(mm) | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 |

Max. Printing Size(mm) | 900×1950 | 900×2350 | 1100×2350 | 1100×2750 |

Product Detailed

| Feeder Unit(servo drive) ※ Originally imported lead edge feeding table and trasmission from Sun Automation(USA), to ensure long-term board feeding accuracy and paper feeding stability. ※ The diameter of the feeding roller increased, reducing board pressure ※ Dust removal device: multiple fans for dust suction, multiple rows of brushes with anti-static system.To make the board clean before entering into printer unit. ※ Original Sun transmission from USA: accurate bard feeding, accuracy within +/-1mm, stable performance and high running speed. ※ Original Sun lead edge feeding table from USA: The feeding table is CNC machined from the whole cast aluminum material without deformation. Stable operation, accurate feeding, high running speed and durability. ※ Other companies use domestic transmission , which are noisy, poor in feeding accuracy, unstable in operation and often maintenance . ※ The overall suction device can be raised by about 150mm, which is convenient for maintaining and brush change. ※ Multi-row brush and anti-static system, and anti-jam device. |

| Printer Unit with Vacuum Transfer (servo drive) ※ Full-servo non-stop plate change, quickly correct the inclination generated when the plate is fixed, and reach the correction range. ※The whole process with vacuum trasnfer, high over-lapped printing accuracy. ※SUN Single Doctor Blade inking system ※ The unit is widened to help the ink dry and ensure the over-lapped printing accuracy (Optional: small infrared drying device). ※ Independent servo motor drive with safety performance: 1. Driven by servo motor of anilox roller. 2. Printing cylinder servo motor drive. 3. Vacuum box servo motor drive. ※ The vaccum chamber with ceremic wheel for board transfer. (the surface of the wheel is ceramic, which is resistance and longevity) ※ Quick roll change device, take about 30 minutes to change. |

| Varnish Unit ( Work as printer unit also ) ※ Water-based varnish or UV varnish can be selected for coating during production. ※ The printing unit is widened, which helps the drying speed of the varnish. ※ Equipped with board jam detecor to make the operation safer and more reliable. |

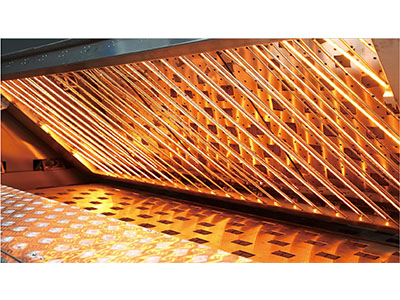

| Dryer Unit ( Infrared dryer or UV dryer system as optional ) ※ According to the width of the board, the infrared lamps can be controlled in sections to save energy. ※ The infrared drying can quickly dry the water-based varnish on the surface of the printed board. |

| Slotter Unit ( Double creaser ) ※ The lateral movement:With lead screw and linear guide. Motorized and PLC control , which makes the movement more flexible and accurate. ※ Double slotting structure, the paperboard below 800mm does not need to take off the knife , and the use is more flexible. ※Servo motor drive for the unit. |

| Die-cutter Unit ( Independent Servo Motor Drive ) ※ Driven by servo motor, the vibration of the printing unit is effectively reduced, and the printing is more accurate. ※ The anvil cover roller compensation is driven by an independent motor, which controls the speed of the anvil cover roller , and the compensation range is +6MM, so that the speed of the anvil cover roller and the die cylinder are consistent. ※ Die-cutting registration adjustment is driven by PLC servo. |

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more