High Speed Fixed Printing Press Machine

T-ONE fixed printing press machine adopts the international advanced design concept, passed the European CE certification, in accordance with European and American manufacturing standards,designed and manufactured for high requirements, reliable functionality and safety

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-FS900X2000 High Speed Fixed Printing Press Machine

(fixed structure,top printing,vacuum transfer)

Main Parameters:

Model | T-FS920 | T-FS924 | T-FS1224 | T-FS1228 |

Max. Speed(pc/min) | 350 | 350 | 350 | 300 |

Max Feeding Size(mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 |

Min Feeding Size(mm) | 300×600 | 300×600 | 350×600 | 350×600 |

Skip Feeding(mm) | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 |

Max. Printing Size(mm) | 900×1950 | 900×2350 | 1100×2350 | 1100×2750 |

Product Detailed

Feeder Unit

1. Original imported SUN Lead Edge Feeder to promise long - term feeding precision and stability.

2. Enlarged feeding roll diameter can reduce paperboard flute damage.

3. Several row brushes and anti-static system to keep the paperboard clean before coming into printer unit. So printing quality is promised.

Printer Unit with Vacuum Transfer

1. Quick lock printing plate setting system on both R/L sides to achieve precise alignment.

2. Vacuum paperboard transfer for high register precision.

3. Widened unit width is helpful for ink dry and printing register.

4. The vacuum box transfer roller is cast in aluminum alloy, and the surface is coated with ceramic, which increases the contact friction coefficient between roller and paperboard.

5. Imported Doctor Blade Inking System: Chamber is made of special non-metal material which will never get rusted and easy for cleaning; quick change of doctor blade is available.

Varnish Unit ( Work as printer unit also )

1. Water-based varnish or UV varnish could be used .

2. Widened unit width is helpful for varnish dry.

3. For safe operation, paperboard blocked sensor applied.

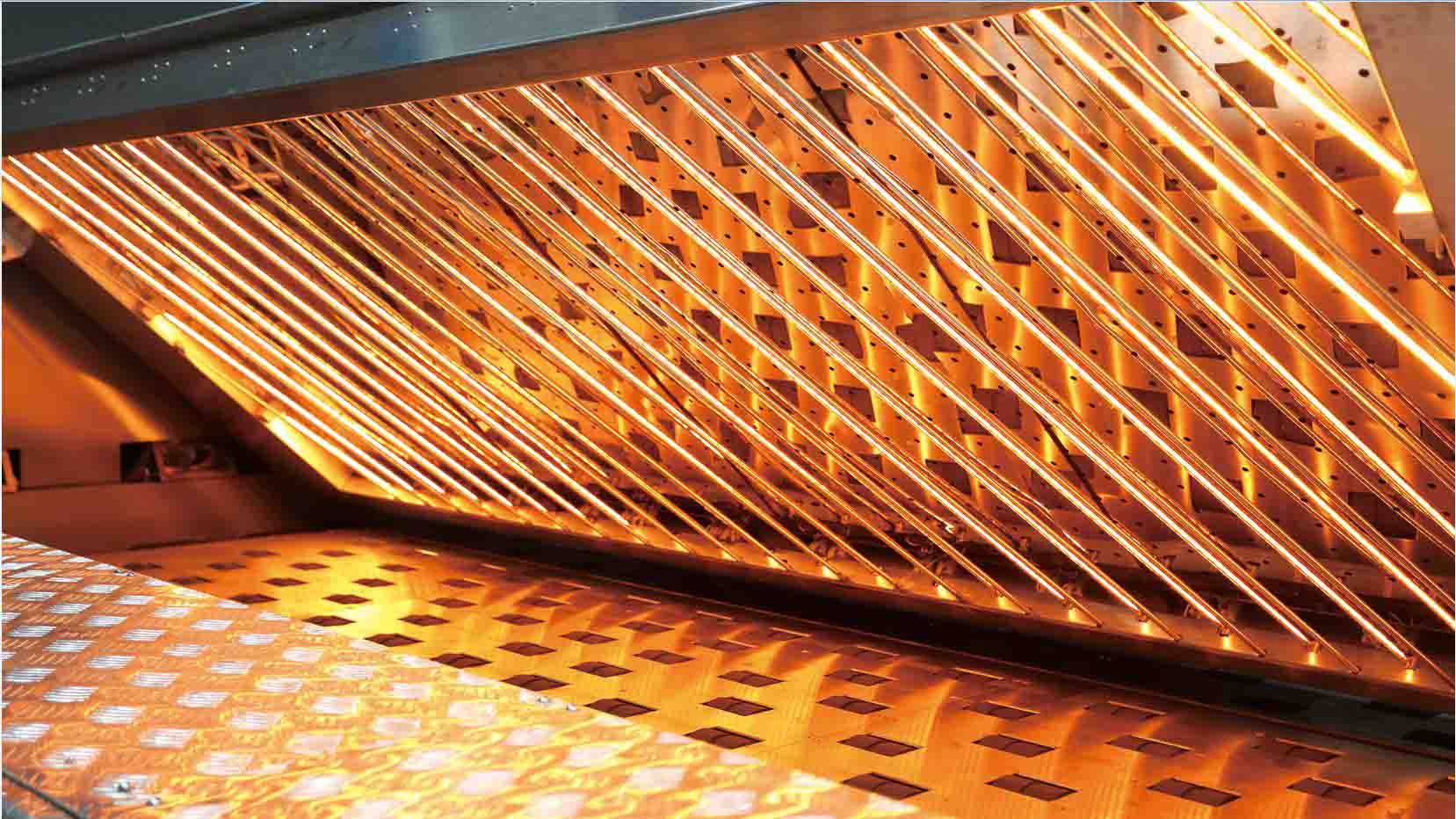

Dryer Unit( Infrared dryer or UV dryer system as optional )

1. IR lamp is segmented control. So lamp could be set according to paperboard width to save power.

2. UV dryer makes UV coated paperboard surface to dry very quickly. So ink smear will not happen and also the machine speed improved with high quality product.

Slotter Unit ( Double creaser )

1. Single shaft with double slotting knives. Internal gear adjusts the height of the carton box and prevents the lubricant oil from spilling or leaking onto the paperboard.

2. Slotting bosses move along linear guide rail and are driven by lead screws for flexible and precise movement.

3. Double creaser slotter unit: use large creasing structure,more perfect creasing effect; the outer is made of urethane ,which will not damage the paperboard.

4. Lateral movement of pre-creasing roll, creasing roll and slotting bosses are digitally controlled by motor and PLC.

Die-cutter Unit ( Independent Servo Motor Drive )

1. Servo motor drive for the unit, no any vibration to the printer unit. So the printing register promised.

2. Anvil cylinder speed compensation achieved by adopting independent motor,the compensation scope is 5mm.

3. Die-Cutting register controlled by PLC with servo motor drive.

4. Micro-grinding system is available.(Optional)

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more