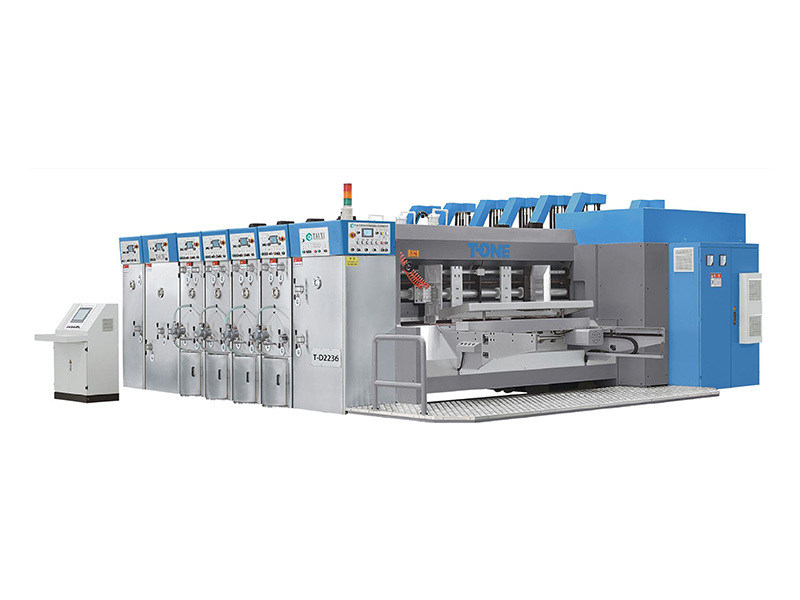

High Speed Flexo Rotary Die-cutter

T-ONE high speed flexo rotary die-cutter with self-locked system for all roller gap adjustments.and can store different orders by independent computer control table

- T-ONE

- Foshan,China

- Information

- Video

- Download

TD1200X2400 High Speed Flexo Rotary Die-cutter

(Roll to roll transfer)

Main Parameters

Model | TD920 | TD1224 | TD1228 | TD1426 | TD1628 | TD1632 | TD2236 | TD2242 | TD2636 |

Max. Speed(pcs/min) | 300 | 250 | 230 | 200 | 180 | 180 | 140 | 130 | 100 |

Max Feeding Size(mm) | 900×2000 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 | 1600×3200 | 2200×3600 | 2200×4200 | 2600×3600 |

Min Feeding Size(mm) | 260×600 | 320×600 | 320×600 | 420×600 | 450×600 | 450×600 | 500×700 | 500×700 | 500×700 |

Skip Feeding (mm) | 1200×2000 | 1500×2400 | 1500×2800 | 1700×2600 | 1900×2800 | 1900×3200 | 2500×3600 | 2500×4200 | 2800×3600 |

Max. Printing Area(mm) | 900×1960 | 1200×2360 | 1200×2760 | 1400×2560 | 1600×2760 | 1600×3160 | 2200×3560 | 2200×4160 | 2500×3560 |

Min. Slotting Reverse knife(mm) | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 360×95×360×95 | 360×95×360×95 | 360×95×360×95 |

Min. Slotting Normal knife(mm) | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 150×150×150×150 | 150×150×150×150 | 150×150×150×150 |

Slotting Depth (mm) | 250 | 300 | 300 | 350 | 400 | 400 | 700 | 700 | 700 |

Feeder Unit Featrues:

A. Sun Automation Lead Edge Feeding System

●With three shafts and strong vacuum suction. So the feeding precise and stability are promised for both high speed and low speed.

● Feeding stroke could be adjusted to reduce feeding roller impression.

● Frequency converter control the vacuum to match different size paperboard.

● High stability with high speed, less noise and variation.

● Left and right side guides are PLC controlled and motorized.

● Motorized backstop forward and backward movement.

● Continuous or skip feeding is available with counter.

B. Dust Removal System

● Dust removal system with several brushes and segmented vacuum sheet cleaner.

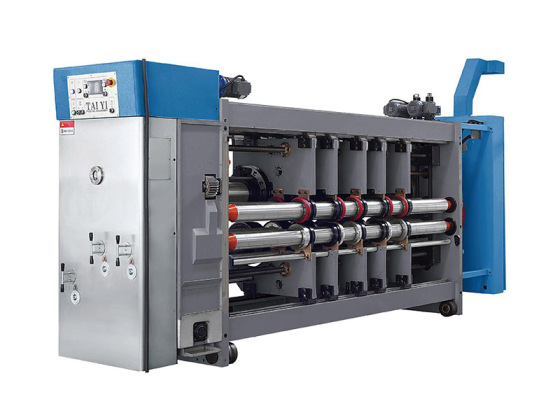

C. Upper and Lower Feeding Roll

● Upper feeding roll wrapped with wear resistant rubber.

● Lower feeding roll surface knurled and chrome-plated.

● Self-locked system applied for adjusting feeding roll gap, range is 0-12mm.

●Cam bearing applied for impression roll power transmission, wearing reduced and also transfer more stable.

D. Units Open and Close, Zeroing System

● With clutch for the machine open and close to avoid damage the machine while in moving.

● Main motor protected from starting up when units are not completely closed and locked.

● Encoder applied for all units with zeroing function.

● Zeroing function used for sample making, generally speaking two paperboards are enough.

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more