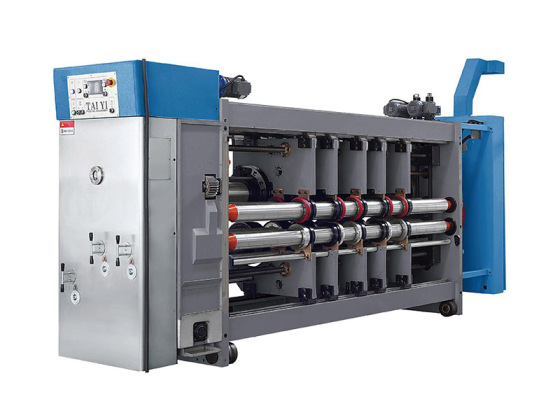

High Speed Printer Slotter Diecutting Machine

1. T-ONE high speed printer slotter diecutting machine can store common orders up to 99999, change orders quickly, and very easy to

operate.

2. The printing slotting machine with function of auto-zero and auto-reset.

3. Remote maintenance device is optional for the printer slotter diecutting machine

- Information

- Video

- Download

TD1400X2600 High Speed Printer Slotter Diecutting Machine

(roll to roll transfer)

Main Parameters

Model | TD920 | TD1224 | TD1228 | TD1426 | TD1628 | TD1632 | TD2236 | TD2242 | TD2636 |

Max. Speed(pcs/min) | 300 | 250 | 230 | 200 | 180 | 180 | 140 | 130 | 100 |

Max Feeding Size(mm) | 900×2000 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 | 1600×3200 | 2200×3600 | 2200×4200 | 2600×3600 |

Min Feeding Size(mm) | 260×600 | 320×600 | 320×600 | 420×600 | 450×600 | 450×600 | 500×700 | 500×700 | 500×700 |

Skip Feeding (mm) | 1200×2000 | 1500×2400 | 1500×2800 | 1700×2600 | 1900×2800 | 1900×3200 | 2500×3600 | 2500×4200 | 2800×3600 |

Max. Printing Area(mm) | 900×1960 | 1200×2360 | 1200×2760 | 1400×2560 | 1600×2760 | 1600×3160 | 2200×3560 | 2200×4160 | 2500×3560 |

Min. Slotting Reverse knife(mm) | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 360×95×360×95 | 360×95×360×95 | 360×95×360×95 |

Min. Slotting Normal knife(mm) | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 150×150×150×150 | 150×150×150×150 | 150×150×150×150 |

Slotting Depth (mm) | 250 | 300 | 300 | 350 | 400 | 400 | 700 | 700 | 700 |

Rotary Die-cutter Unit

Rotary Die-Cutter Unit Features:

A. Die Cylinder (Lower)

● Ground and chromed high quality steel

● Dynamic balanced for stable running.

● Fixing hole distance is 50mm lateral.

● Creasing height is 22.60mm.

● Wooden die thickness is 13mm.

B. Anvil Cylinder (Upper)

● Ground and chromed high quality steel

● Dynamic balanced for stable running.

● Anvil cover thickness is 10mm,width is 252mm.

● Side to side oscillation of anvil cylinder( 50mm).

● Motorized gap adjustment between anvil roll and die cylinder.

C. Self-locking System Adopted for Pulling Roll Gap.

D. Cam bearing applied for the Pull Roll working, wear reduced and run more stable.

E. Cutting Registration Adjust System

● Planetary gear system

● Cutting registration controlled by PLC and motorized, 360°adjust.

● Lateral registration controlled by PLC and motorized, range ±10mm.

F. Anvil Speed Compensating System with Dependent Motor, range ±3mm.

G. With Anvil Grinding System for Keeping Smooth.

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more