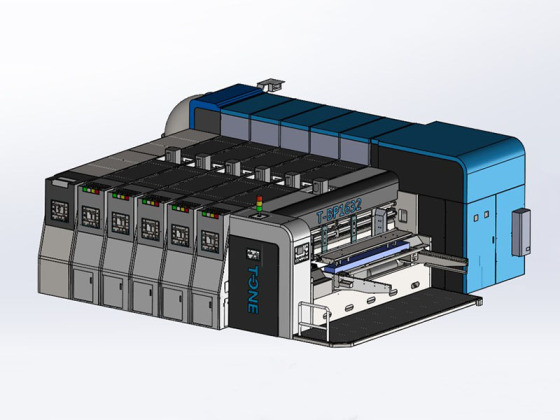

Bottom Corrugated Box Printing Machine

T-ONE fixed bottom corrugated box printing machine with new appearance of latest industrial design concept,combline with Taiyi & SUN Automation's years of techinical experiences

Wall of the bottom corrugated printing machine thickened to 80MM,main drive bearings enlarged into two specifications

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-BF1200X2400 Bottom Corrugated Box Printing Machine

(Fixed structure,servo drive,bottom printing,vacuum transfer)

Main Parameters:

Model | T-BF1224 | T-BF1228 | T-BF1628 | T-BF1632 |

Max.Speed(pcs) | 250 | 230 | 220 | 200 |

Max.Feeding size(mm) | 1200x2400 | 1200x2800 | 1600x2800 | 1600x3200 |

Min.Feeding size(mm) | 320x600 | 320x600 | 450x600 | 450x600 |

Skip Feeding(mm) | 1500x2400 | 1500x2800 | 1900x2800 | 1900x3200 |

Max.Printing Area(mm) | 1200x2360 | 1200x2760 | 1600x2760 | 1600x3160 |

Standard Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 | 7.2 |

Min.Slotting/Reverse Knife(mm) | 260x65x260 x65 | 260x65x260 x65 | 260x65x260 x65 | 260x65x260 x65 |

Min.Slotting /Normal Knife(mm) | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 |

Max.Slotting Depth(mm) | 300 | 300 | 400 | 400 |

Product Detailed:

FEEDER UNIT

※Origin Sun Leading Edge Feeder :High Accuracy,Range+/-1mm . High Speed, as high as 1,000,000-1,300,000m2/day

※Independent servo drive

※Continous or skip feeding available (with counter).

※ Leading edge roller feeding,stroke is adjustable,and less impression for pull roller

※ Frequency control of vacuum air flow and pressure to match the cardboard size

※ Two-layer pull roller, inner layer soft, outer hard, both to insure wear-resistant,and reduce the pressure to avoid wrap board

PRINTER UNIT

※Vacuum transfer table(surface of roller made by ceramic)。

※Quick lock printing plate setting system on both R/L sides to achieve precise alignment.

※Servo drive for printing phase adjust

※Automatic cleaning switch device, the ink recovery more complete; automatic plates reset system after cleaning

※Ceramic roll or SUN doctor blade inking system(optional) are available,to improve printing quality and easy operation

INDEPENDENT CREASER

※Independent creaser,with servo drive.

※Creaser moving with lead screw with linear guide quick moving and precise。

※Pre-creaser , creaser , base of knife lateral movement with digital control

※Ceaser:1:1 large dimension of creaser get perfect creaser line lower crease with anvil no crush boards(optional)

※Large pre-creaser,ceaser can be fitted with half thick and half thin

SLOTTER UNIT

※ Two shafts doulbe slotting with servo drive

※ Lateral knife moving with lead screw with linear guide quick moving and precise

※ Pull roller,base of knife lateral movement with digital control

※ Single shaft with upper /lower knife optional

※ 1:1 large dimension of creaser get perfect creaser line lower crease with anvil no crush boards

※ Lateral knife moving with lead screw with linear guide quick moving and precise。

※ Upper/Lower slotting knife base are connected by the transmission shaft,so that the upper/lower slotting knife alignment is accurate

and the service life of the knife is prolonged.

※Cutting paper structure before trimming knife

DIE-CUTTER UNIT

※ Servo drive for die-cutter

※ Independ compensate drive motor compensate the speed of Anvil roll , compensate range 5MM

※ SUN Die-cutting Precision Control System

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more