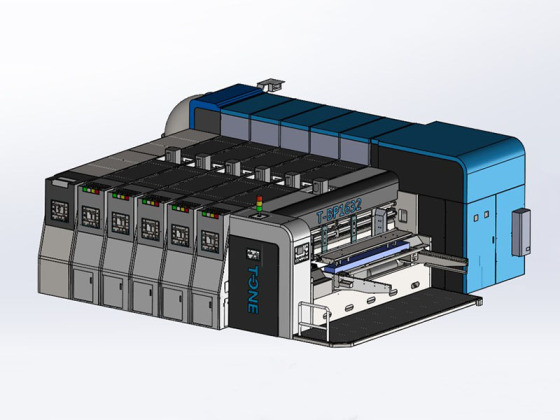

Corrugated Cardboard Bottom Printing Machine

T-ONE corrugated cardboard bottom printing machine adopts with

Origin SUN High Speed Leading Edge Feeder

Origin SUN High Speed Vacuum Transfer

Origin SUN Doctor Blade System

Origin SUN Die-cutting Precision Control System

Origin SUN Fixed Open Structure

T-ONE Non-Stop Servo Drive for quick Printing Die Change

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-BF1600X2800 Corrugated Cardboard Bottom Printing Machine

(Fixed structure,bottom printing,servo drive,vacuum transfer)

Main Parameters:

Model | T-BF1224 | T-BF1228 | T-BF1628 | T-BF1632 |

Max.Speed(pcs) | 250 | 230 | 220 | 200 |

Max.Feeding size(mm) | 1200x2400 | 1200x2800 | 1600x2800 | 1600x3200 |

Min.Feeding size(mm) | 320x600 | 320x600 | 450x600 | 450x600 |

Skip Feeding(mm) | 1500x2400 | 1500x2800 | 1900x2800 | 1900x3200 |

Max.Printing Area(mm) | 1200x2360 | 1200x2760 | 1600x2760 | 1600x3160 |

Standard Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 | 7.2 |

Min.Slotting/Reverse Knife(mm) | 260x65x260 x65 | 260x65x260 x65 | 260x65x260 x65 | 260x65x260 x65 |

Min.Slotting /Normal Knife(mm) | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 |

Max.Slotting Depth(mm) | 300 | 300 | 400 | 400 |

Machine Brief Introduction:

● New appearance of industrial design

● Machine wall thickened to 80MM

● Main drive bearings enlarged into two specifications

● Protection covers added to the running wheels

● Left/right side guide link with linear screw with independent drive for the gap adjust . Piano protector(prevent particle get into)

● Height adjustable row brushes and anti-static system

● Enlarged diameter for anilox roll and printing rubber roll

● Quick roll change device added to make roll change more convenient

● Independent creaser unit for better paperboard folding

● Double slotting structure, which can be suitable for various box types

● Lateral movement built in gear box ,machine start up this lateral will automatic moving, lateral range +/-50MM

● Individual motorize position control for pull roll moving

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more