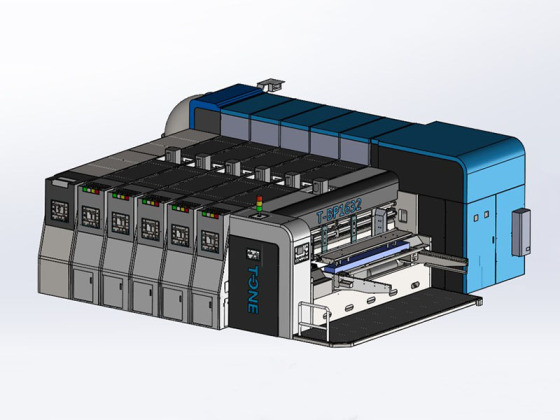

High Speed Carton Bottom Printing Machine

T-ONE high speed carton bottom printing machine,the main bearings of feeding roll, the impression roll, the anilox roll and the printing cylinder head are upgraded two grades to improve lifetime of the equipment and reduce the maintenance cost.

The wall of the carton box printing machine thickned to 80MM, which makes the machine more stable.

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-BF1200X2800 High Speed Carton Bottom Printing Machine

(Fixed structure,servo drive,bottom printing,vacuum transfer)

Main Parameters:

| Model | T-BF1224 | T-BF1228 | T-BF1628 | T-BF1632 |

| Max.Speed(pcs) | 250 | 230 | 220 | 200 |

| Max.Feeding size(mm) | 1200x2400 | 1200x2800 | 1600x2800 | 1600x3200 |

| Min.Feeding size(mm) | 320x600 | 320x600 | 450x600 | 450x600 |

| Skip Feeding(mm) | 1500x2400 | 1500x2800 | 1900x2800 | 1900x3200 |

Max.Printing Area(mm) | 1200x2360 | 1200x2760 | 1600x2760 | 1600x3160 |

Standard Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 | 7.2 |

| Min.Slotting/Reverse Knife(mm) | 260x65x260 x65 | 260x65x260 x65 | 260x65x260 x65 | 260x65x260 x65 |

| Min.Slotting /Normal Knife(mm) | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 |

Max.Slotting Depth(mm) | 300 | 300 | 400 | 400 |

Machine Brief Introduction:

● All frame walls thickness improve to 80MM for more steady operation.

● New outlook of industrial design

● Quality of main transmission bearing are two grades higer

● All movement wheels enclosed with covers

● Using Piano seal cover lead on side guide on Feeder Unit

● Movable dust removal device in Feeder Unit

● Bigger diameter of anilox roller and rubber roller in Printer Unit

● Fast change device for rollers easy operation

● Independent creaser unit for better performance

● Double slotter structure to fit various types of carton

● 50mm side to side oscillation of anvil cylinder device

● Motorized pull ring adjustment

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more