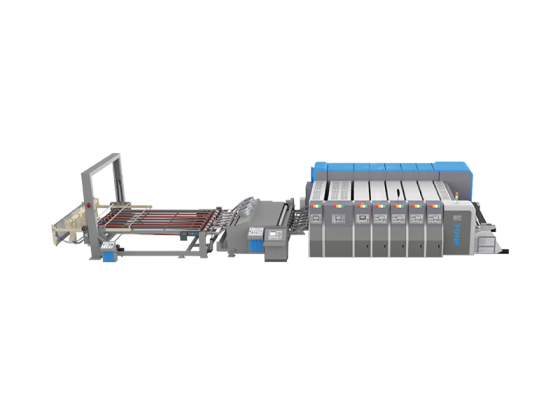

Vacuum Transferring Printing Machine

1. T-ONE printing machine :continuous and skip feed availbale( with counter)

2. Leader edge feeder,auto feeding stroke adjust,less pressure for pull roller.

3. The printing machine converter controlled the vacuum and pressure according to board size.

4. Pull roll of the printing machine with two layer rubber, inner soft and outlayer hard to reduce the board crush.

- T-ONE

- Foshan,China

- Information

- Video

- Download

T-GC900X2400 Vacuum Transferring Printing Machine

Main Parameters:

Model | T-GC618 | T-GC920 | T-GC924 | T-GC1224 | T-GC1228 | T-GC1428 | T-GC1628 | T-GC1632 | T-GC1636 |

Max. Speed(pcs/min) | 350 | 300 | 300 | 250 | 230 | 220 | 180 | 180 | 160 |

Max Feeding Size(mm) | 600×1800 | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 | 1400×2800 | 1600×2800 | 1600×3200 | 1600×3600 |

Min Feeding Size(mm) | 200×435 | 270×600 | 270×600 | 320×600 | 320×600 | 365×600 | 450×600 | 450×600 | 450×600 |

Skip Feeding (mm) | 800×1800 | 1200×2000 | 1200×2400 | 1500×2400 | 1500×2800 | 1700×2800 | 1900×2800 | 1900×3200 | 1900×3600 |

Max. Printing Area(mm) | 600×1760 | 900×1960 | 900×2360 | 1200×2360 | 1200×2760 | 1400×2760 | 1600×2760 | 1600×3160 | 1600×3560 |

Min. Slotting Reverse knife(mm) | 180×55×180×55 | 240×65×240×65 | 240×65×240×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 | 260×65×260×65 |

Min. Slotting Normal knife(mm) | 110×110×110×110 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 |

Slotting Depth (mm) | 200 | 250 | 250 | 300 | 300 | 350 | 400 | 400 | 400 |

General features

CE certificated machine designed with advanced concept, made according to European standards with TAI YI many year experience in producing machines.

The alarm will give warn while unit moving.

The gaps between rolls are motorized with PLC control.

With automatic zero setting and reset function.

Unit features

- Feeder Unit: latest lead-edge feeding table original from Sun Automation, stable and quick.

- Printer Unit: ceramic-coated transition wheels in vacuum tank to increase ability of anti-wear and life; imported doctor blade inking system

- Double creaser Slotter Unit: single shaft with double slotting knives

- Die-Cutter Unit: independent motor for the anvil cylinder speed compensation, the compensation range is ±3.5mm

- Dryer Unit: independent IR drying system is optional

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more