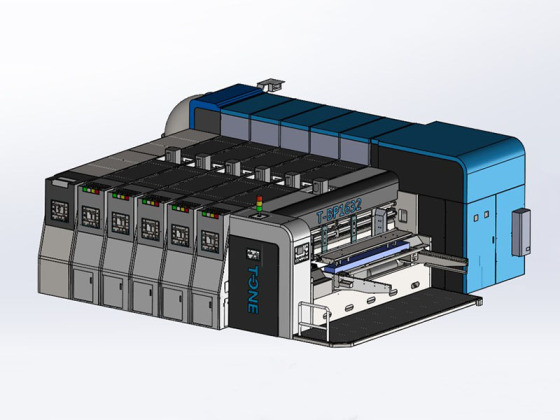

High Speed Corrugated Flexo Bottom Printer

T-ONE high speed corrugated flexo bottom printer every unit can be separated automatically or manually and an audible alarm sounds during the opening and closing for safe operation.

Every unit of the corrugated flexo printer machine is also equipped with an emergency stop switch for increased safety. The machine operator, working inside each unit can stop the unit from moving at any time.

The high speed corrugated flexo bottom printer is also equipped with an automatic lubrication system that keeps the lubricant levels in all of the units uniform at all times.

- T-ONE

- Foshan,China

- Information

T-BP1600X3200 High Speed Corrugated Flexo Bottom Printer

(Movable type,bottom printing,vacuum transfer)

Main Parameters:

Model | T-BP920 | T-BP1224 | T-BP1632 |

Max Speed(Sheet/min) | 300 | 250 | 160 |

Max Feeding Size(mm) | 900x2000 | 1200x2400 | 1600x3200 |

Min.Feeding Size(mm) | 300x600 | 320x600 | 450x600 |

Skip Feeding Size(mm) | 1100x2000 | 1500x2400 | 1900x3200 |

Max Printing Size(mm) | 900x1960 | 1200x2360 | 1600x3160 |

Printing Plate Thickness(mm) | 7.2 | 7.2 | 7.2 |

Min.Slotting/Reverse Knife(mm) | 240x65x240x65 | 260x65x260x65 | 260x65x260x65 |

Min.Slotting/Normal Knife(mm) | 130x130x130x130 | 130x130x130x130 | 130x130x130x130 |

Slotting Depth(mm) | 250 | 300 | 400 |

Machine Brief Introduction

● New Appearance of Industrial Design

● Side frame more thick 70MM

● Main bearing using higher quality

● All the movement with encloser

● Using piano seal cover lead on side guide on Feeder

● Independent feed suction

● Fast change of yellow wheel on Feeder table (without dismount the gear box)

● Dust suction device movement up /down

● Dimension enlarger of rubble roll/ Anilox of printer unit

● Roller fast change device , easy to change

● Inner gear adjustment the boxes height

● Boxes height adjustment and Anti-collision

● Lateral movement for anvil , Range +/-50MM

● Motorize pull ring adjustment

Factory Show

There are several solutions: 1. Check the air pressure, the air pipe of the arm lock cylinder should not leak air, and all the air pipes should not leak air. 2. Adjust the pressure and position of the impression roller. 3. Adjust the parallelism of the impression roller and the printing cylinder. 4. Tighten the ratchets at both ends of the printing plate to make the printing plate tensioned....more